Do you know, that… ?

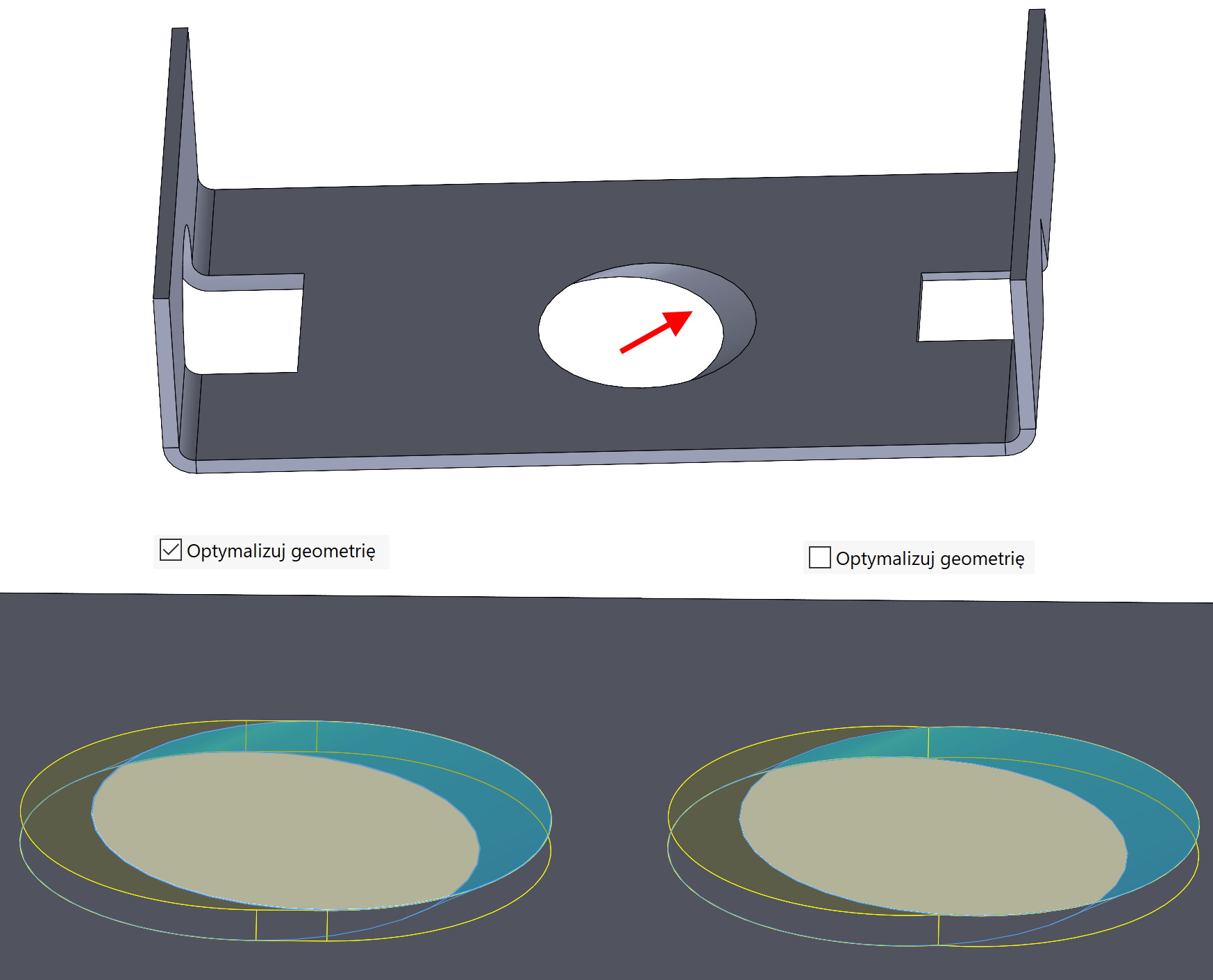

cut perpendicular this operation, which allows you to make a hole in the sheet perpendicular to the wall of the sheet. In practice it can happen, that the cut is not perpendicular – then the flat unfolding shows double edges. Cutting machines need to see a single edge, and that's what it is for cut perpendicular. Of course, I omit specialized 3D cutting machines – but the case under consideration is for a flat cut.

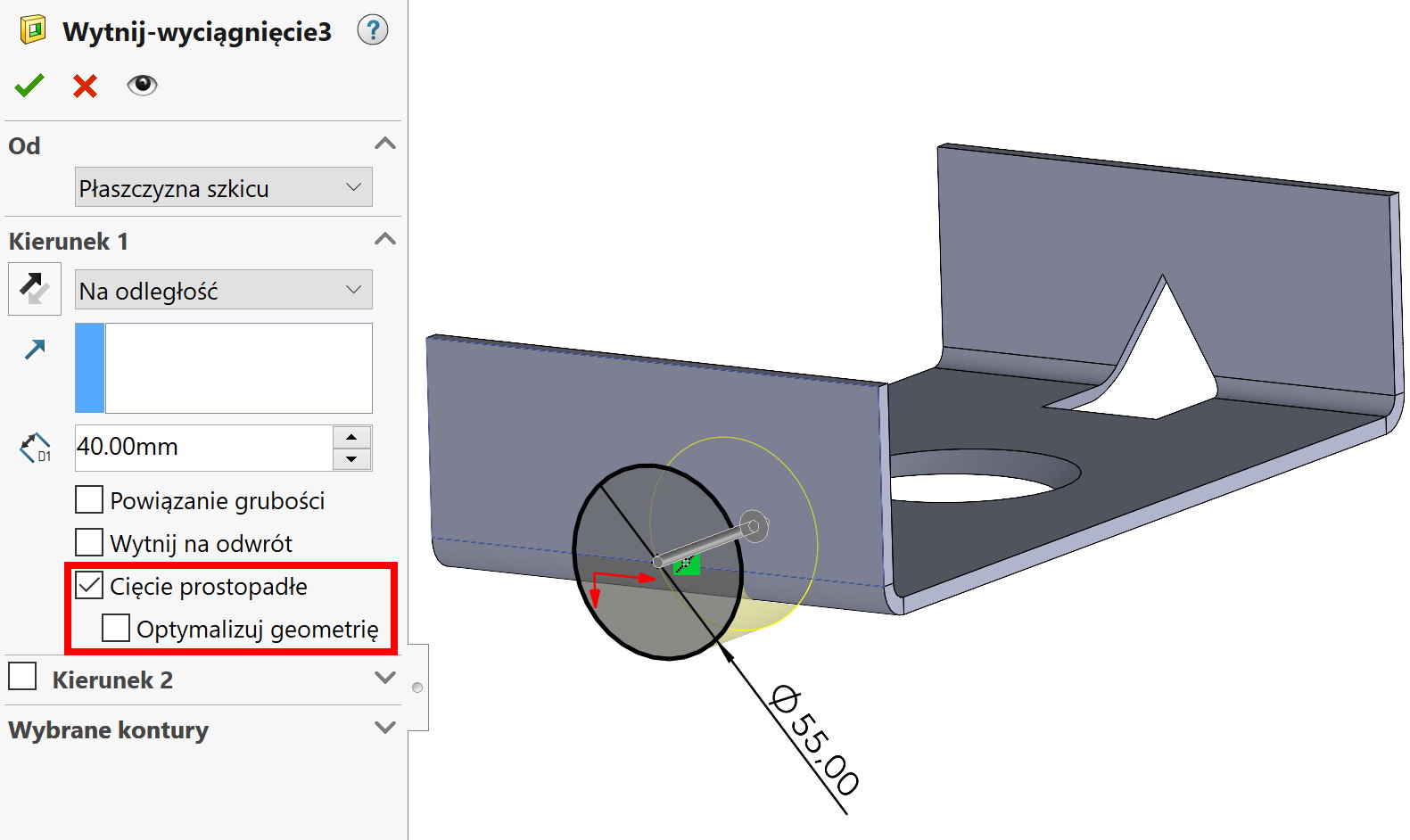

cut perpendicular you can choose right away while cutting out in sheets of metal. However, if this option is unchecked or you are working with the imported file – you can use a separate operation with the same name.

The perpendicular cut includes several important options.

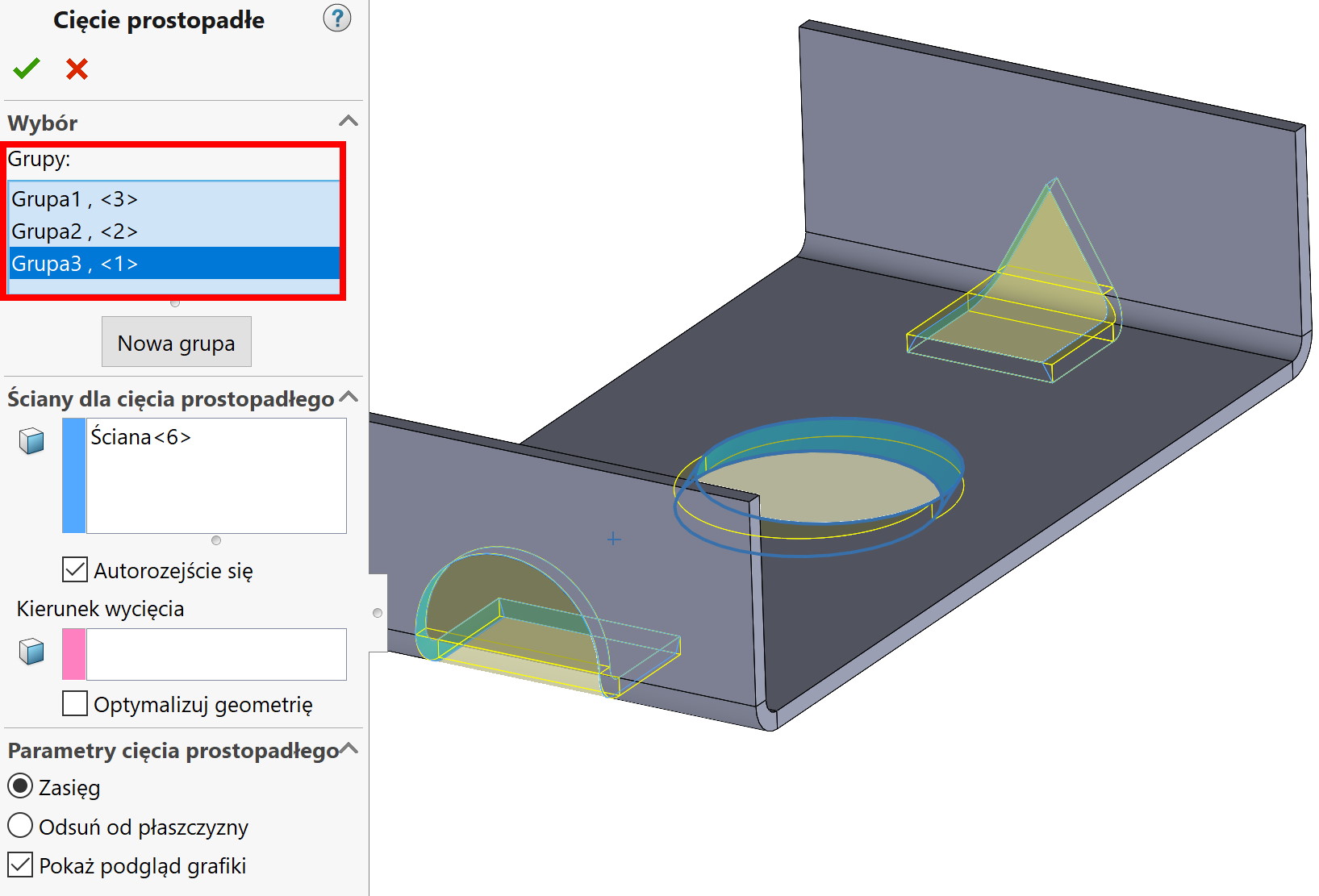

1. Groups.

The ability to select groups makes it easy to select multiple holes “to straighten” in one operation. It works in a similar way to groups in welded structures.

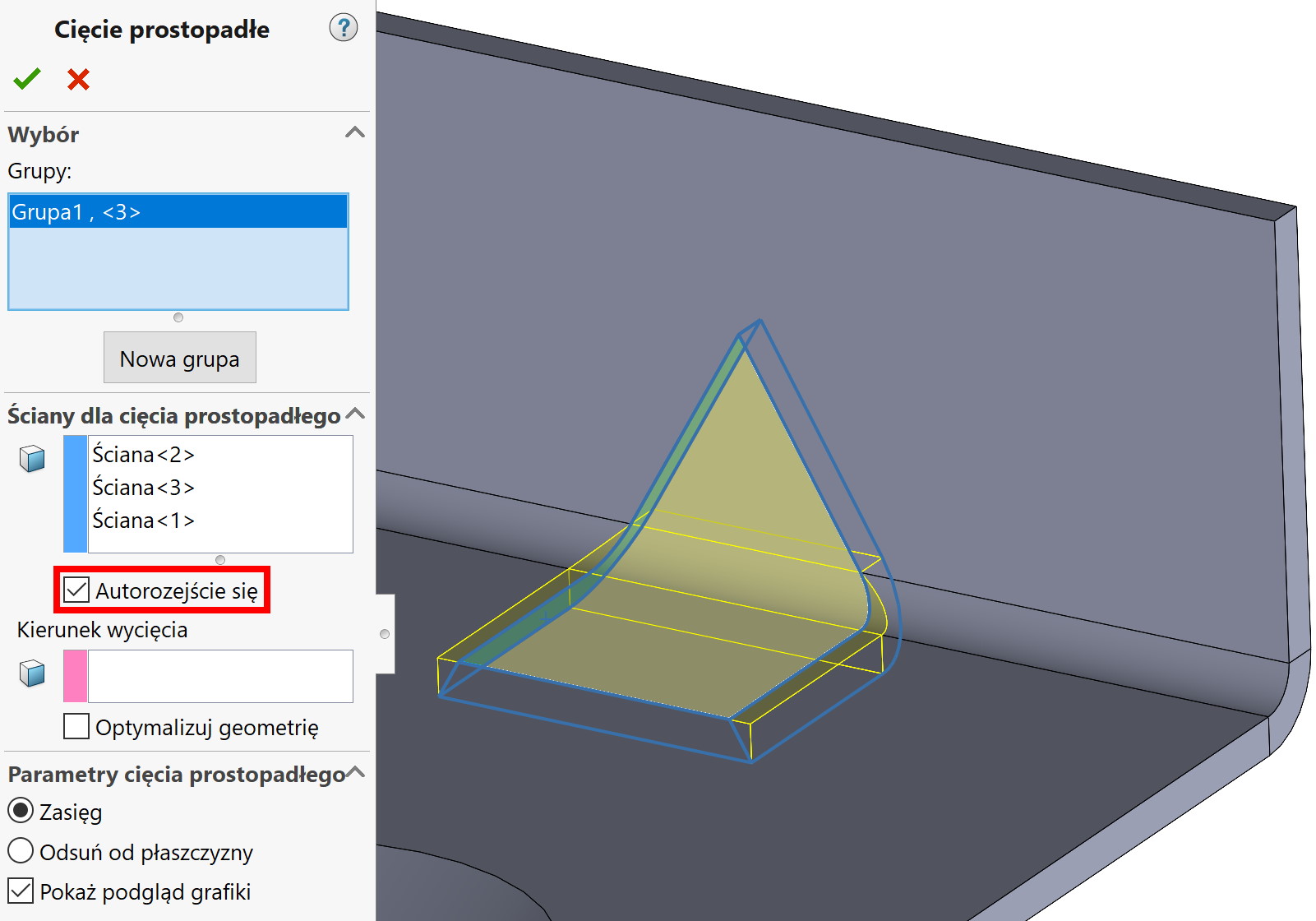

2. Auto-breakdown.

If you want to select multiple faces belonging to the same opening – you don't need to mark every wall. Just turn it on Auto-breakdown.

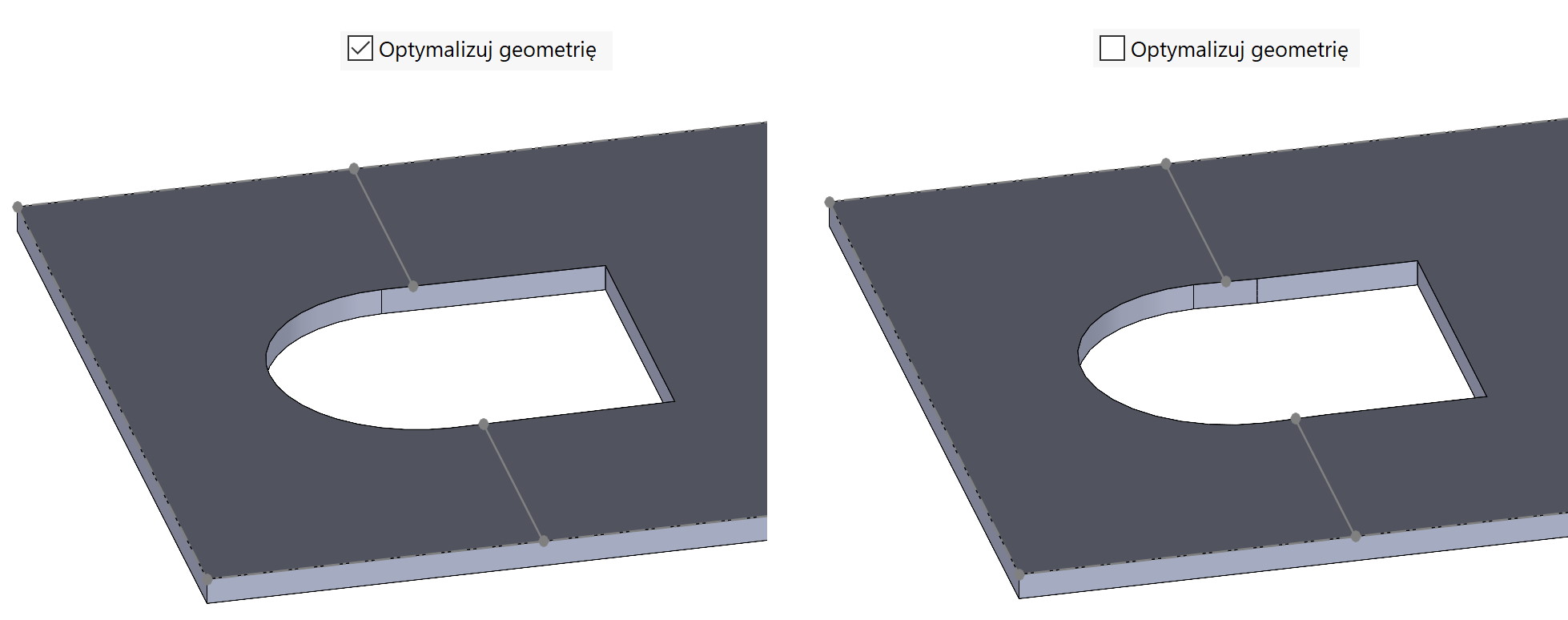

3. Optimize geometry.

Optimization is crucial in unfolded sheets. Selecting this option results in a smoother transition at the edge meeting point. Can be assumed, that the edges create tangent transitions, and when we select optimization, sharp bends arise.

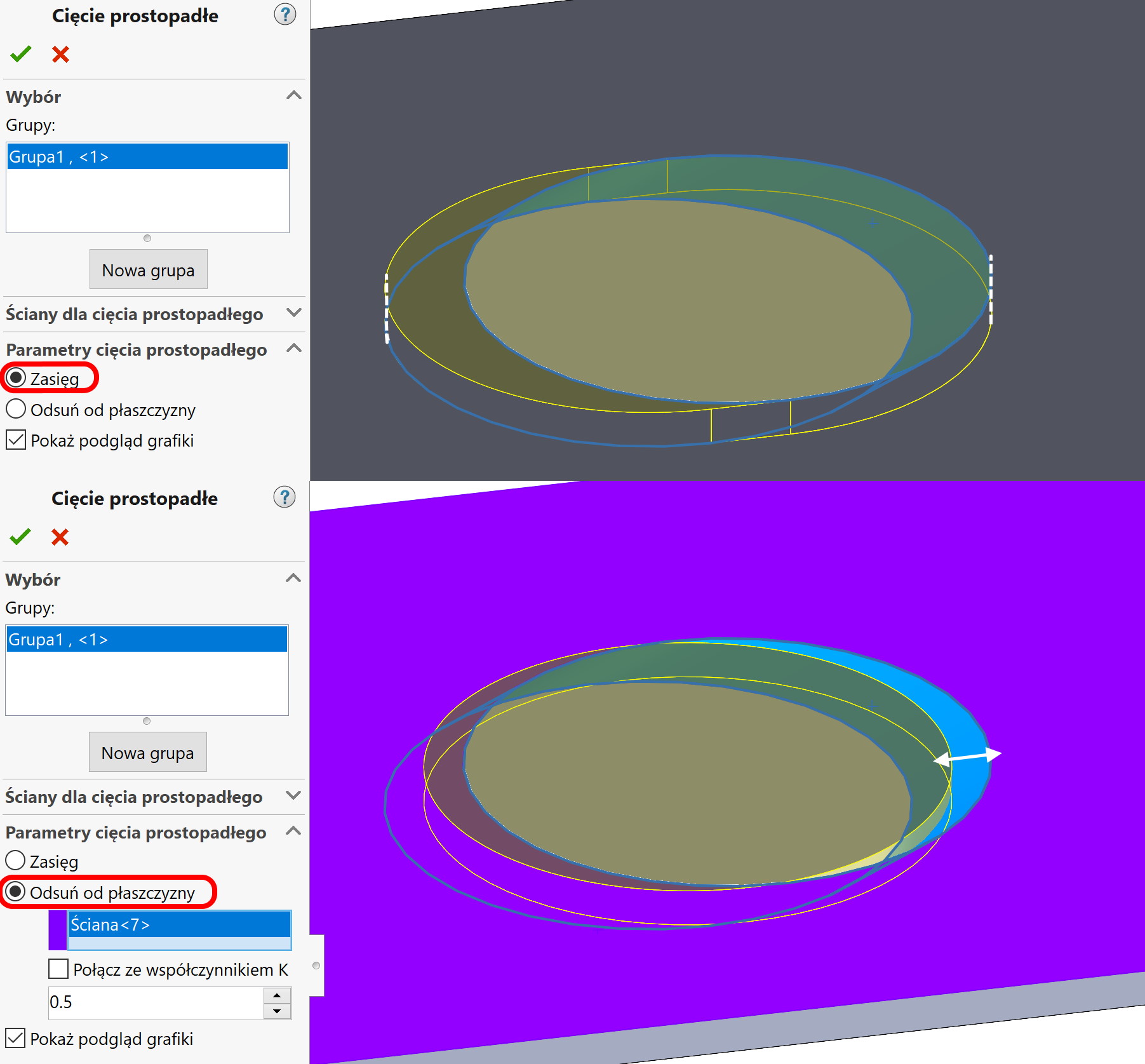

4. Offset from plane.

In a perpendicular cut, the walls are straightened to the most protruding edge. Consequently, it can be assumed, that the hole is getting bigger. If for some reason you don't want this result – select Offset from plane and set values between 0 a 1.