Do you know, that… ?

In SolidWorks sheet metal, you can use forming tools (forming tools), which are located in folders library project. Along with installing the library will be several tools ready. Of course, in a similar way you can prepare your own.

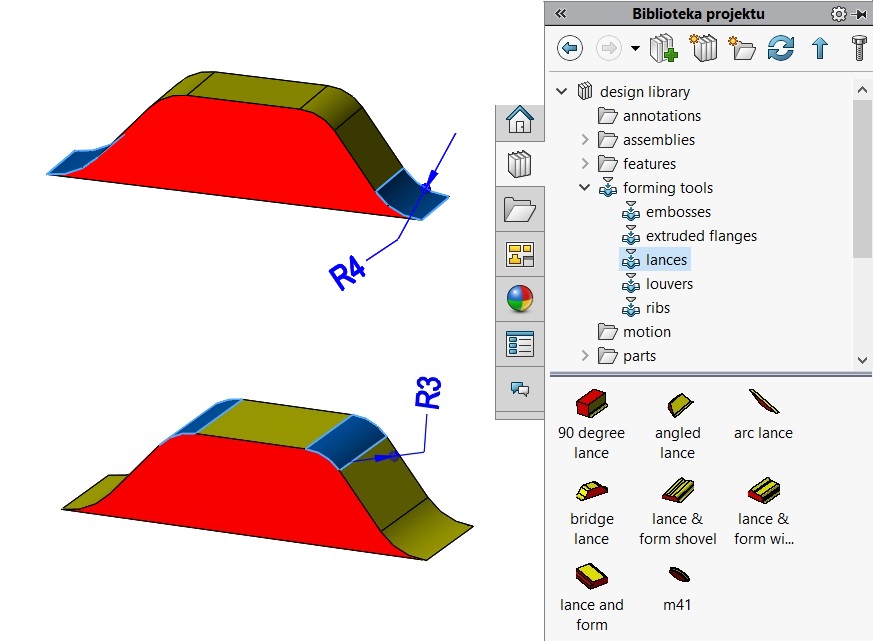

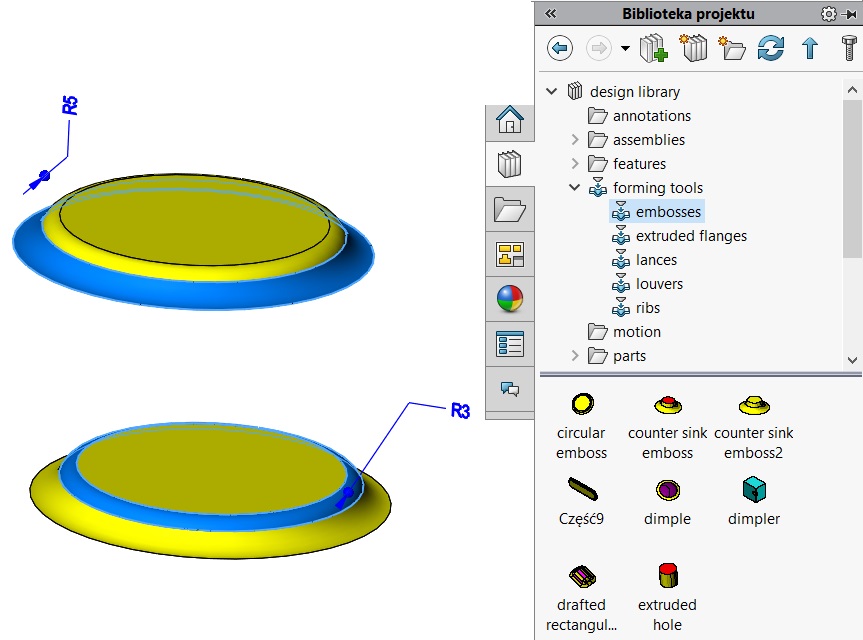

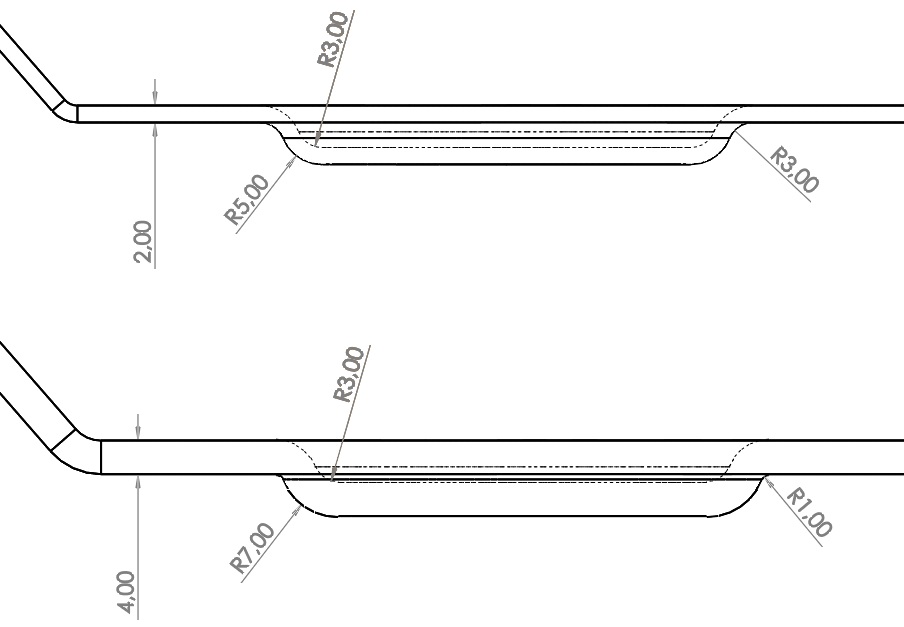

Consider the example of a tool bridge lance. After his opening checked, that the smallest radius is 3mm and 4mm largest. However, it is more important, which will be the inner radius, and which external. Rays mean the de facto, in which the sheet metal tools can be used.

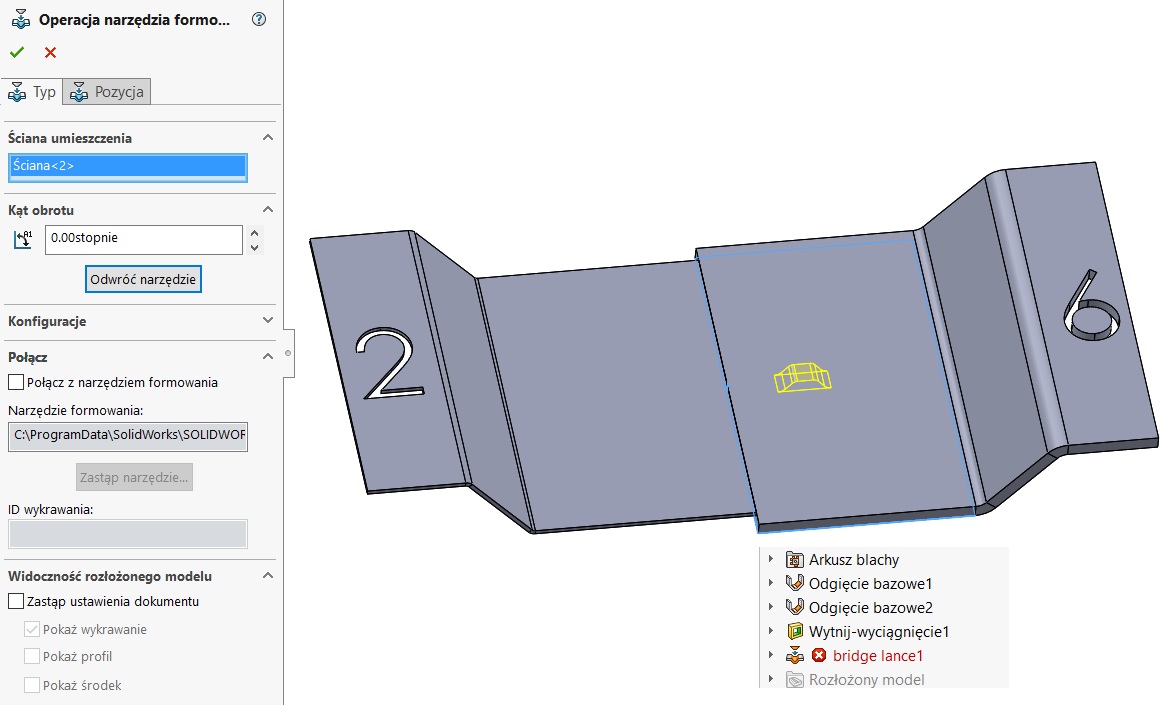

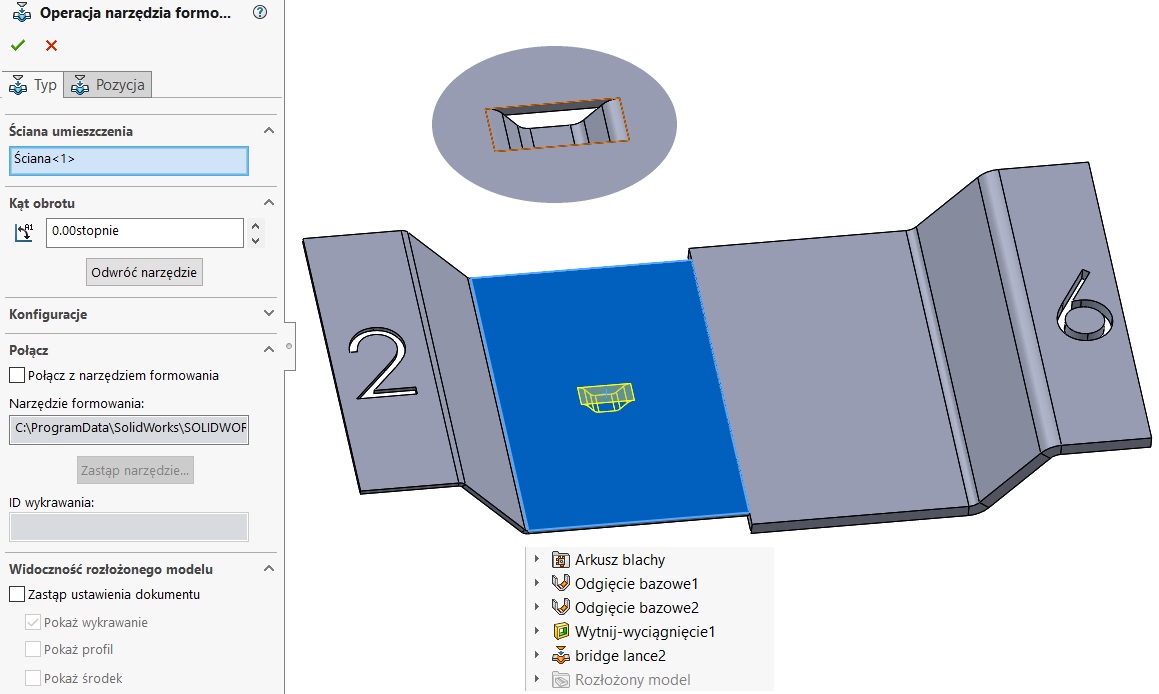

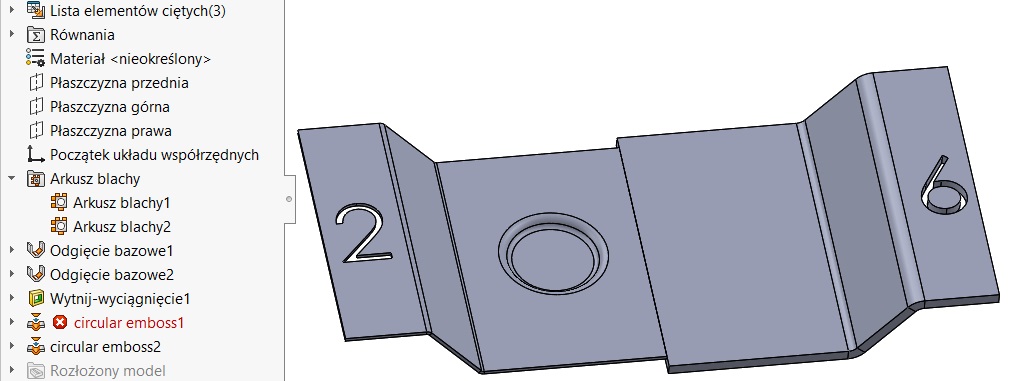

You can easily check this by dragging the tool on the sheet metal thickness specified. In the case of the test sheets are 2 and 6mm thick.

In the case of thicker sheet after dropping the tool tree error occurs – Of course you can not see the sculpted model.

In the second case, when you drag a tool in the thinner sheet, the operation ends successfully.

In that case, what is the thickness of the border?

Since the inner radius of the tool is fixed equal to 3mm, importance is the outer radius (amounting to 4mm). With 4mm sheet will not be a problem, but the greater thickness of a problem due to lack of contact on the inner radius. This is caused by the tool radius of 4mm and the thickness of the sheet. It is easy to calculate, that a sheet of 3mm radius that will 4 – 3 = 1mm, in 2mm sheet will be 2mm, but already this sheet 5mm radius will not be…

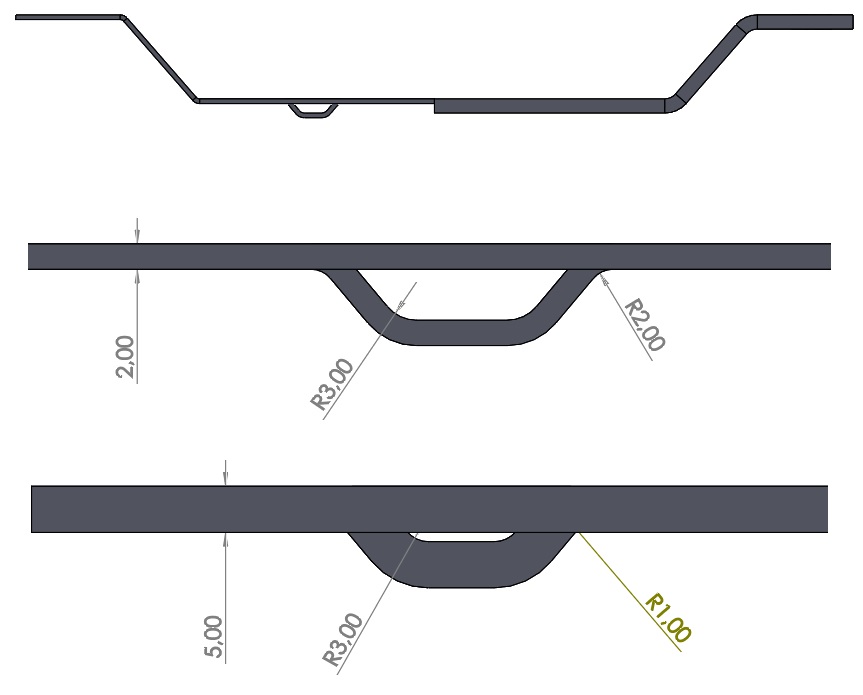

Other tools for knockouts (blind) They behave identically. Circular emboss It has rays 3 i 5mm, which is smoothly applied with sheets of a thickness not exceeding 5 mm.

Similarly, in 6mm thick sheet error occurs.

In this case, the limit thickness is 5mm, below this thickness (e.g. sheet 4mm) It has a radius equal to the outside 1mm – which results from the difference of the radius of the tool 5mm – 4mm plate thickness = 1 mm.

In sum, operations ready knockouts may be used in sheet metal with a thickness dependent on the radii of the molding tool. Due to the fact, after dropping that such operations can edit and change their parameters (including rays), so it is worth preparing tools, rays to be the greatest – matched to the sheets of a maximum permissible thickness. Then you can always change the radius to a smaller. If the sheet is too thick, dropping fails and there is no possibility of editing operations sheet target. The only chance of avoiding error is to change rays in the final molding operation in the library project.