Wanting to show the work of a chain in SOLIDWORKS, roller mechanisms, gears etc. appropriate bonding must be used.

However, the disadvantage of binding is the rigid connection of the components – not taking into account any play. This will be very clearly visible in the case of binding gears, rack and pinion mechanism whether chain formation.

But there is an undoubted advantage – the operation of the above-mentioned devices is very smooth, does not burden the computer.

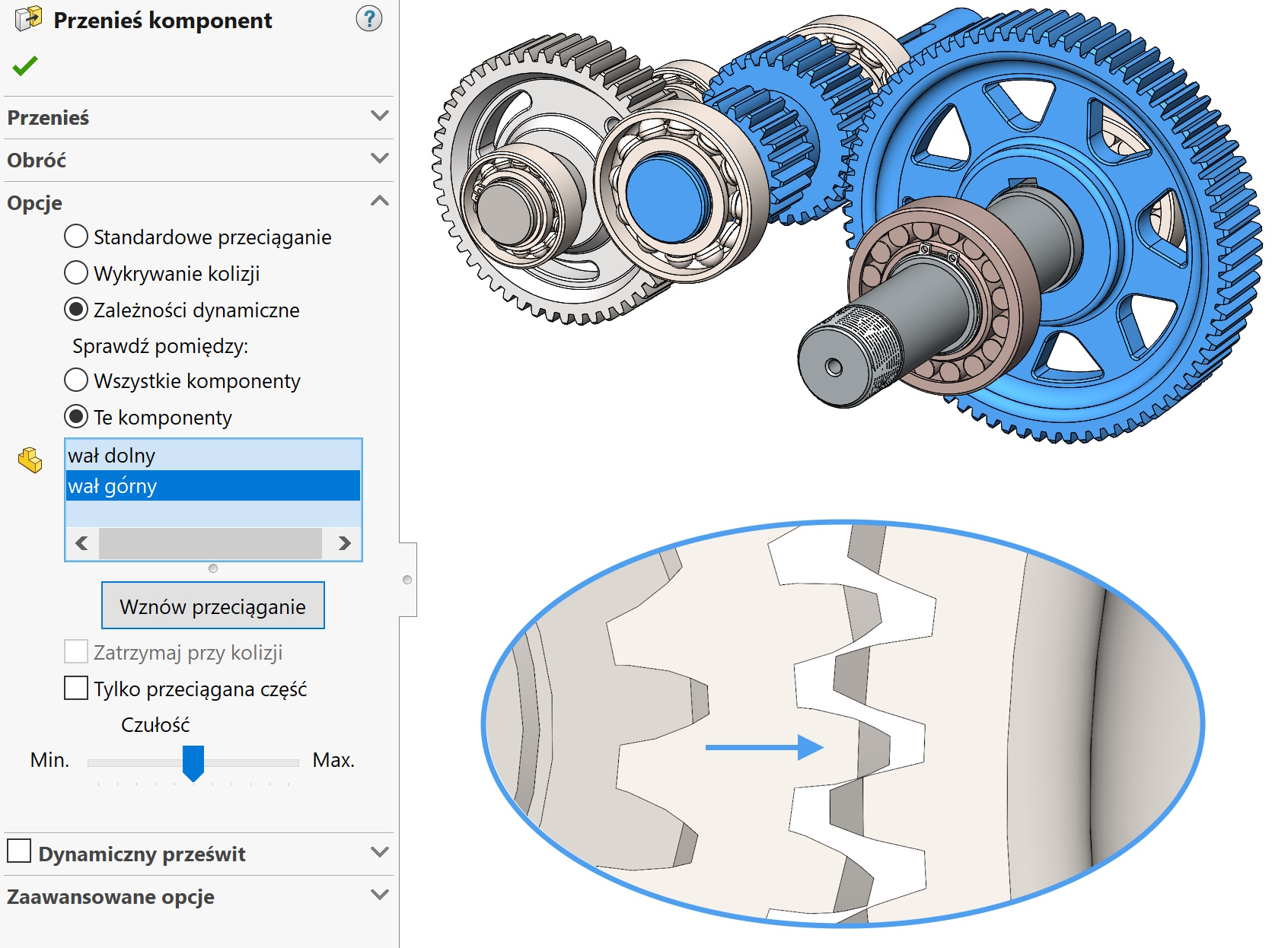

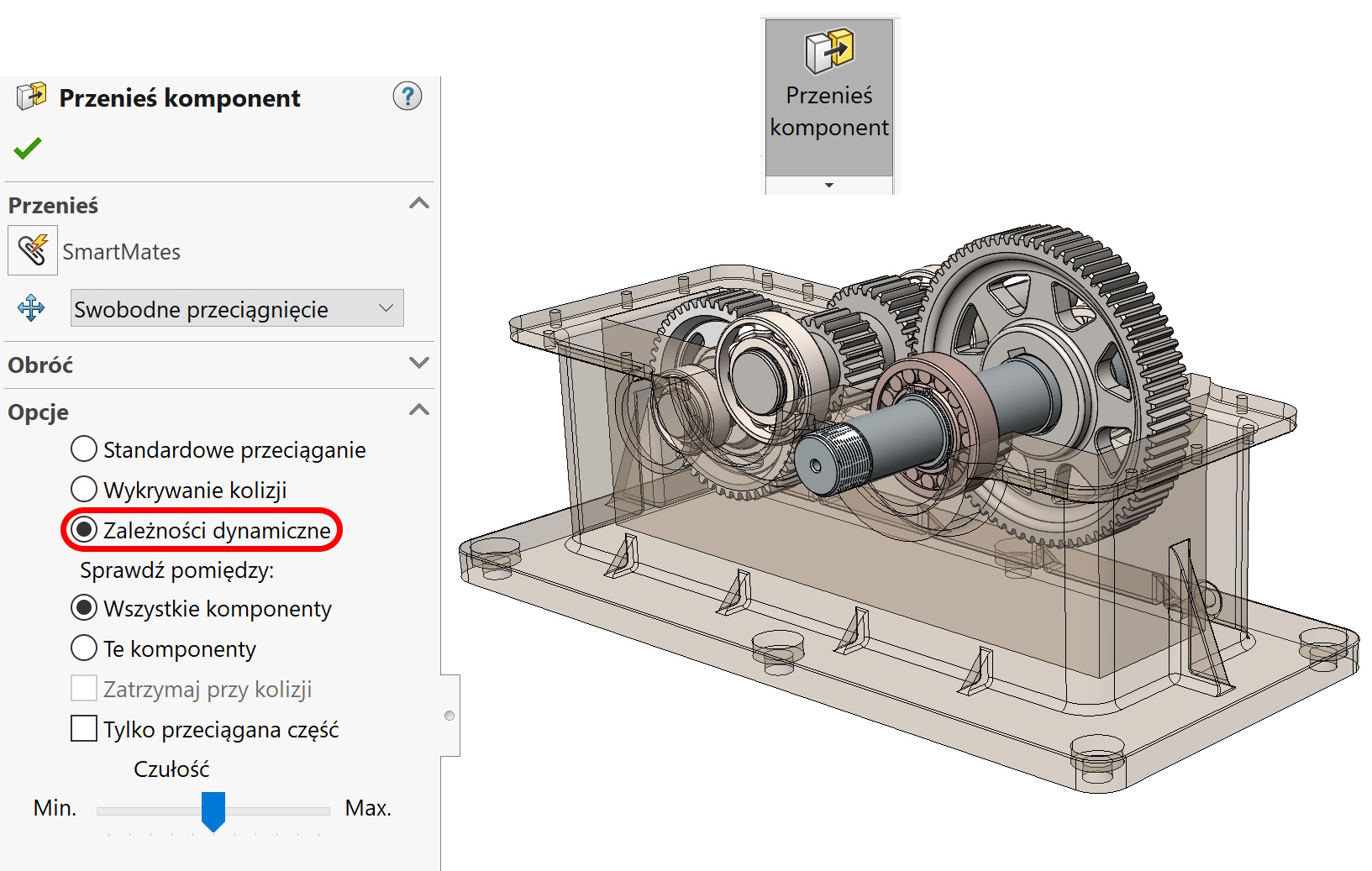

However, if you want to show real performance taking into account the existing gaps, you need to use the command Move component. As a third option they are there Phisical Dynamics , which take into account the mutual contact of the component.

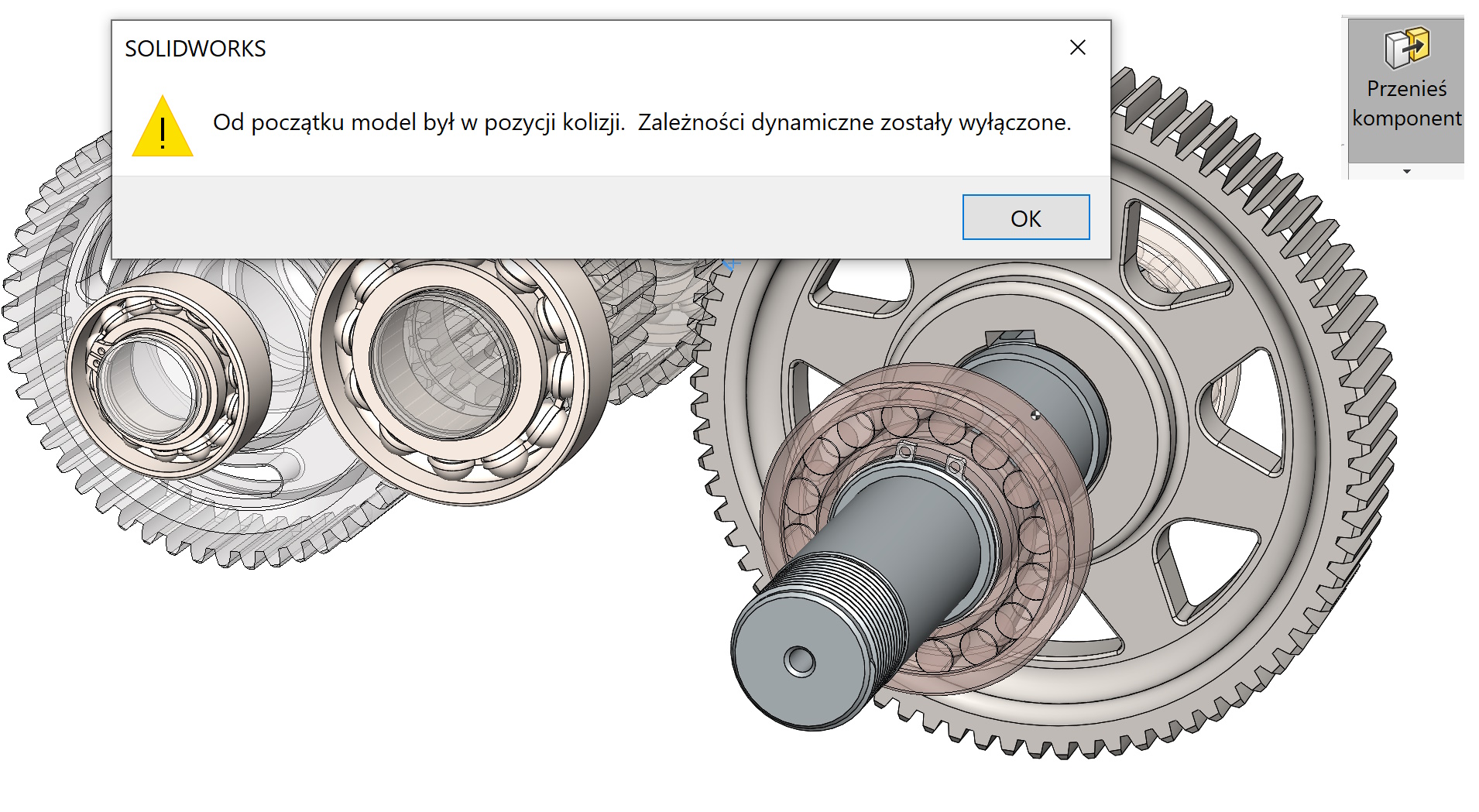

It's a good idea to check before choosing a command detection of penetration, because a previously detected collision prevents this tool from continuing to function.

If there is no collision, you can slowly start rotating/moving the component. When in contact with another component, it will be set in motion. However, given the gear transmission and many wheels connected together, this dynamic relationship causes, that everything starts to cut short…because the program calculates mutual contacts in real time. This is an extremely inefficient solution, however, reflecting real behavior, taking into account any gaps. So they should be used in justified cases and preferably for selected components and not the entire assembly.