Do you know, that… ?

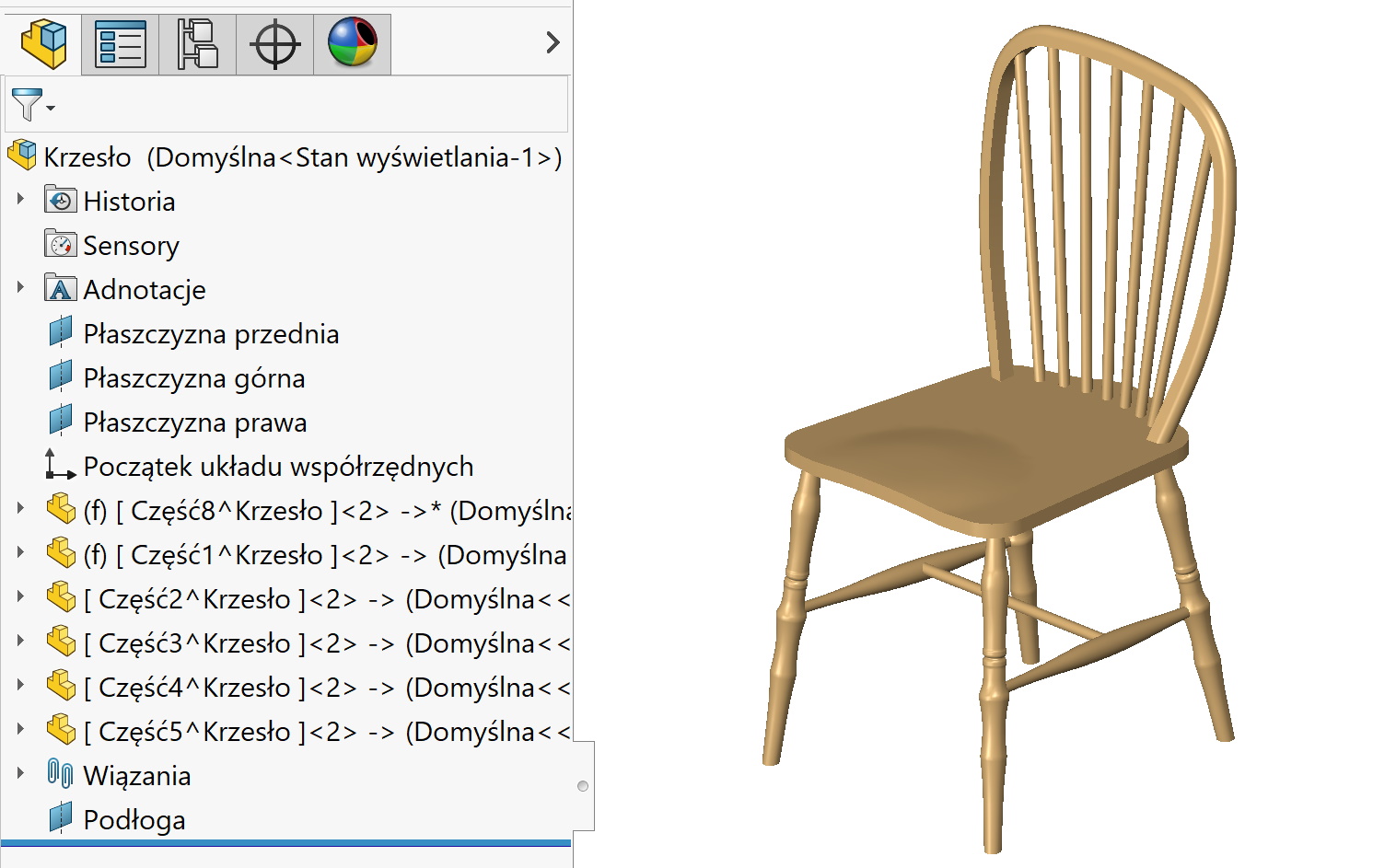

One of the basic analyzes in assemblies is interference and collision detection. It would seem obvious – and yet my experiences training they indicate, that not necessarily…

View, how to correctly perform such verification, depending on the type of assembly.

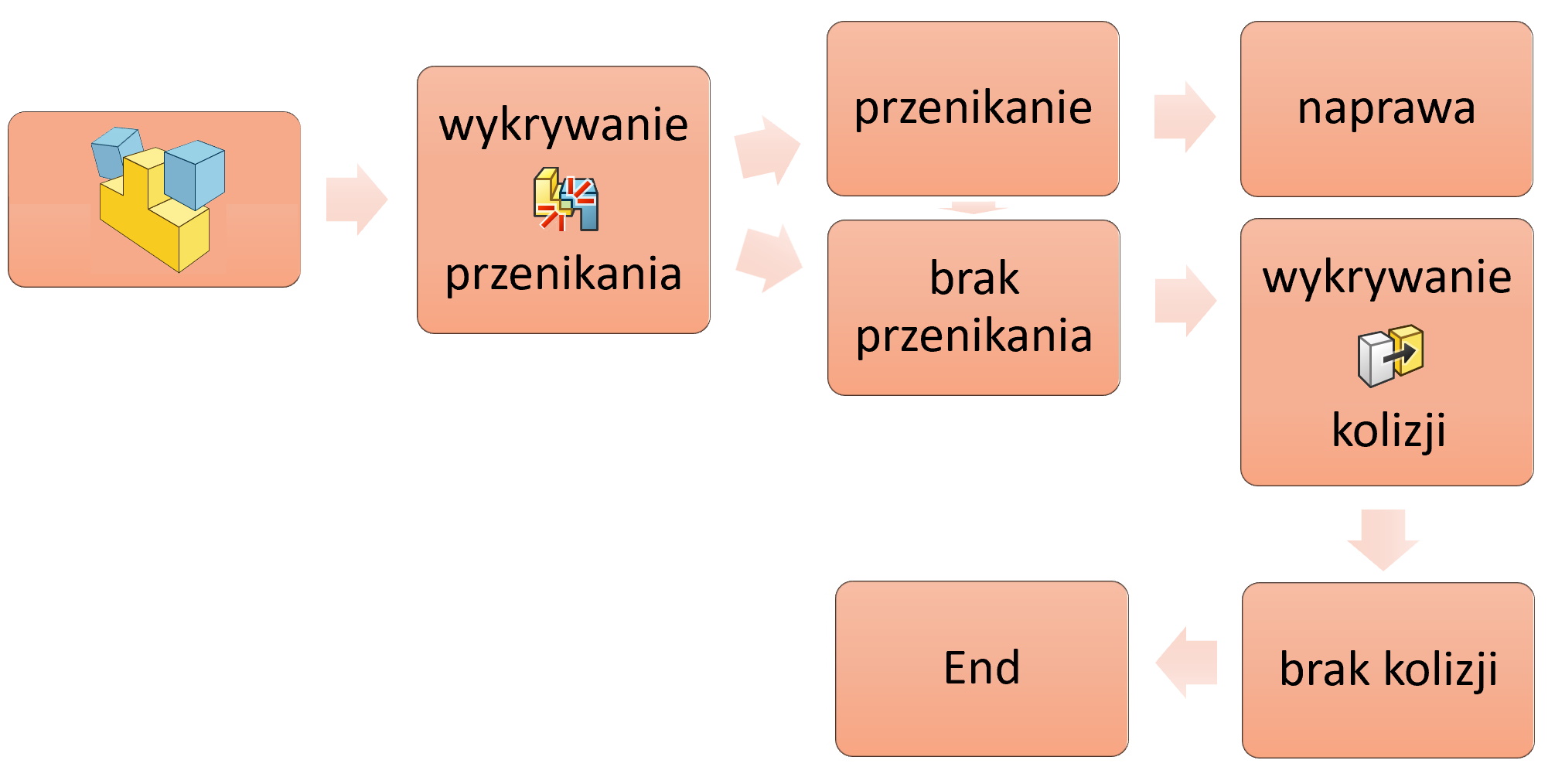

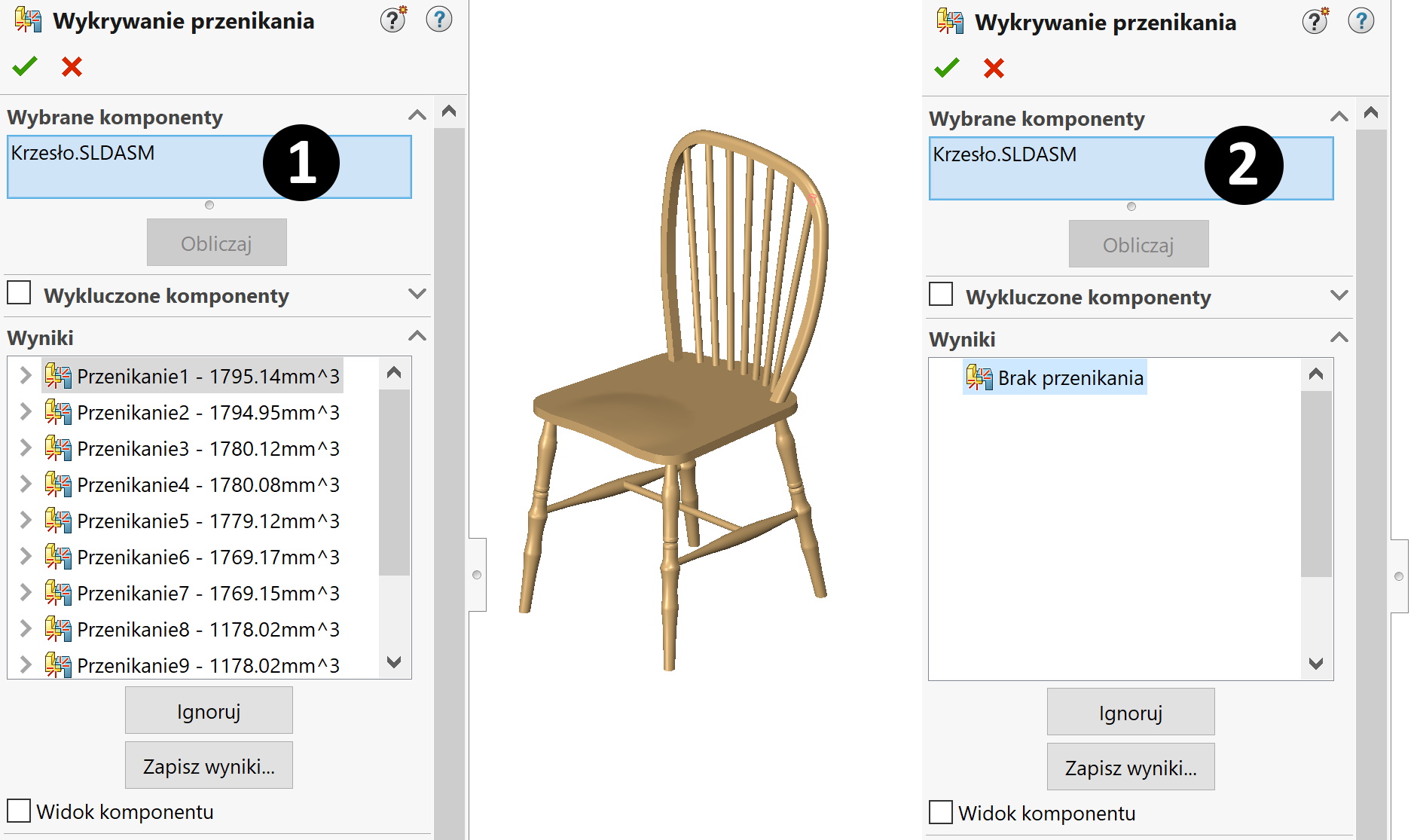

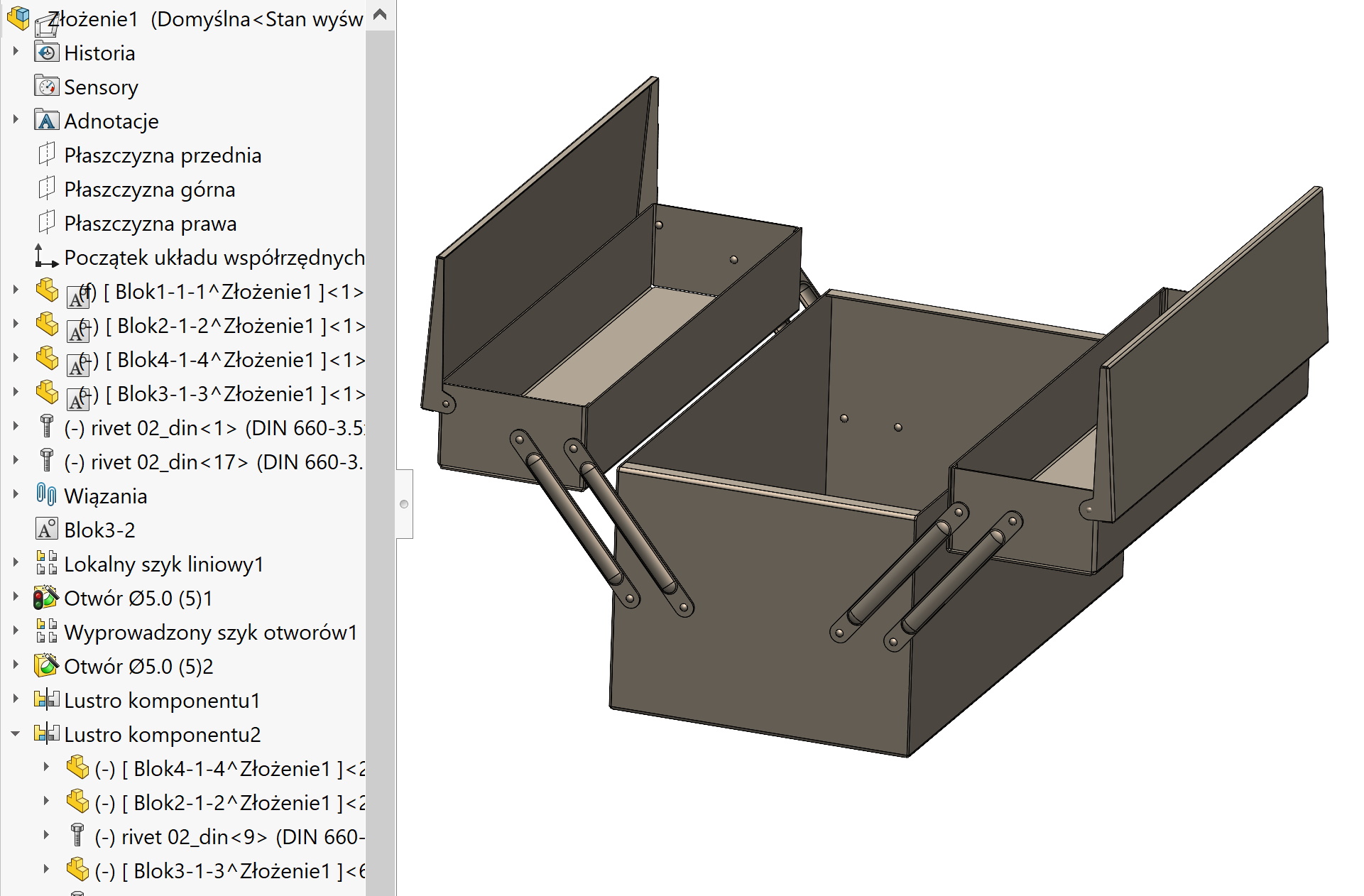

- If the assembly is a static assembly (nothing moves), that's enough to use detection of penetration on the card Review.

If interference is detected (1), then the model should be improved. If there is no diffusion (2), this is where the whole process ends and you don't need to analyze anything else.

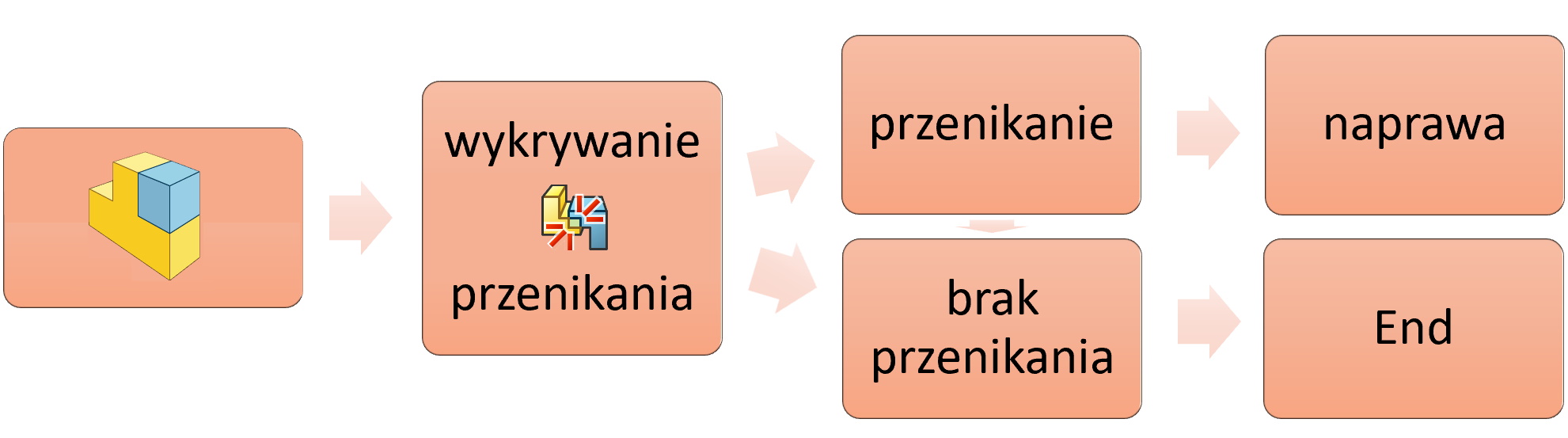

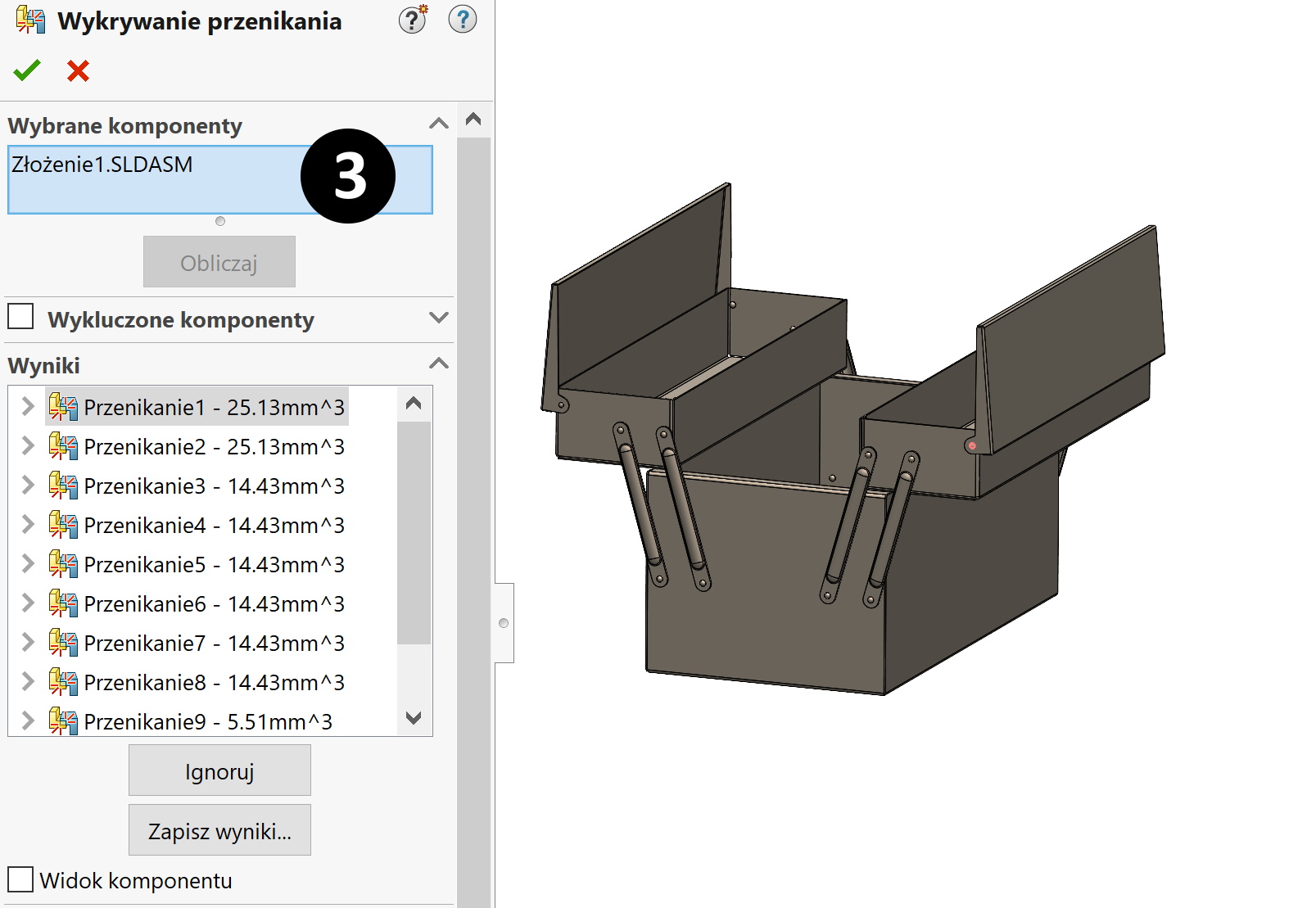

2. For other assemblies, in which components rotate or shift, diffusion detection may be insufficient.

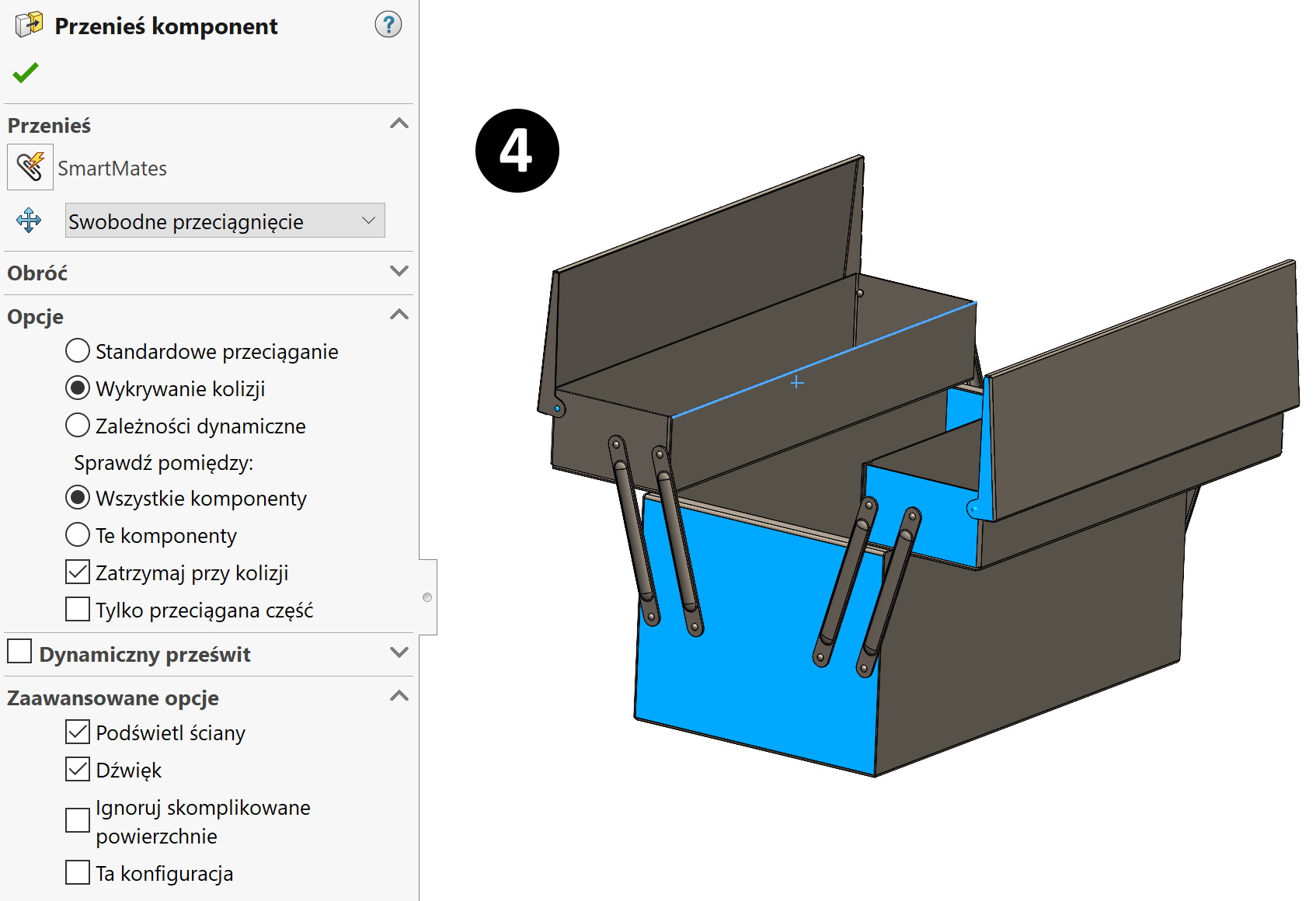

Use the following rule: if there is penetration (3) the model in the place of penetration should be corrected. If there is no penetration at the moment, but the assembly has moving components – go on tab assembling for surgery Move / Rotate. Select Collision detection and stop at a collision (4).

Of course, if there is no collision, the model is built correctly. ATTENTION! If the interference has already occurred, you will start collision detection anyway, the program will inform you, that the model was in a collision from the beginning.