In sheet metal, depending on the cutting method (laser, wire, waterjet, e.t.c.) an appropriate allowance must be provided. Of course, it's not about the bending allowance (the so-called. coefficient k)m only additional material after the outline.

How can you get this?

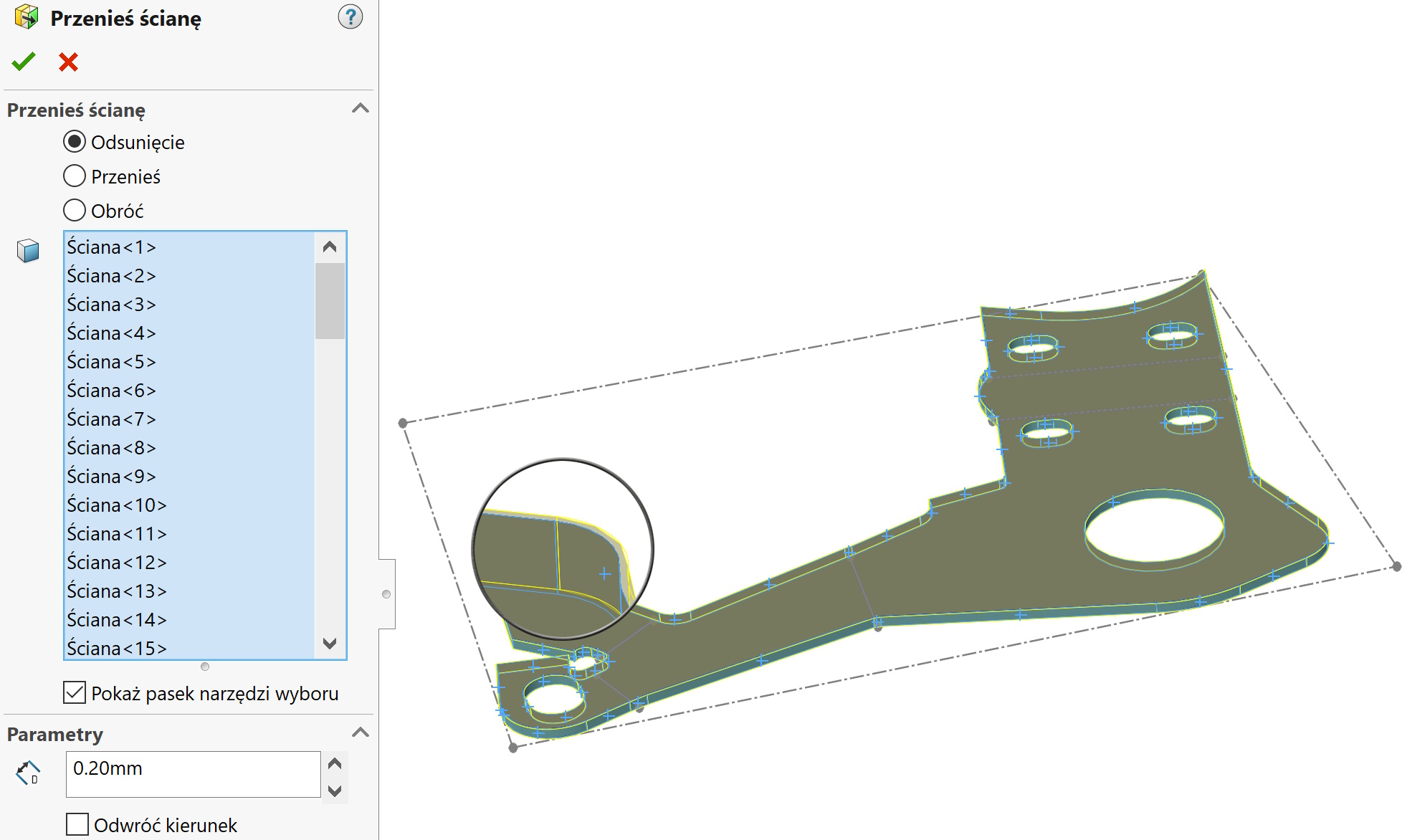

Method 1. Move the walls away.

Use the Move Wall operation to move walls away, after which it will be indented by the required amount. The best way, To avoid selecting all walls manually, select one of them, then selecting Ctrl + A to select all faces in the model. Of course, we only move the walls of the openings or external walls – so two walls upper i lower should be removed from the selection.

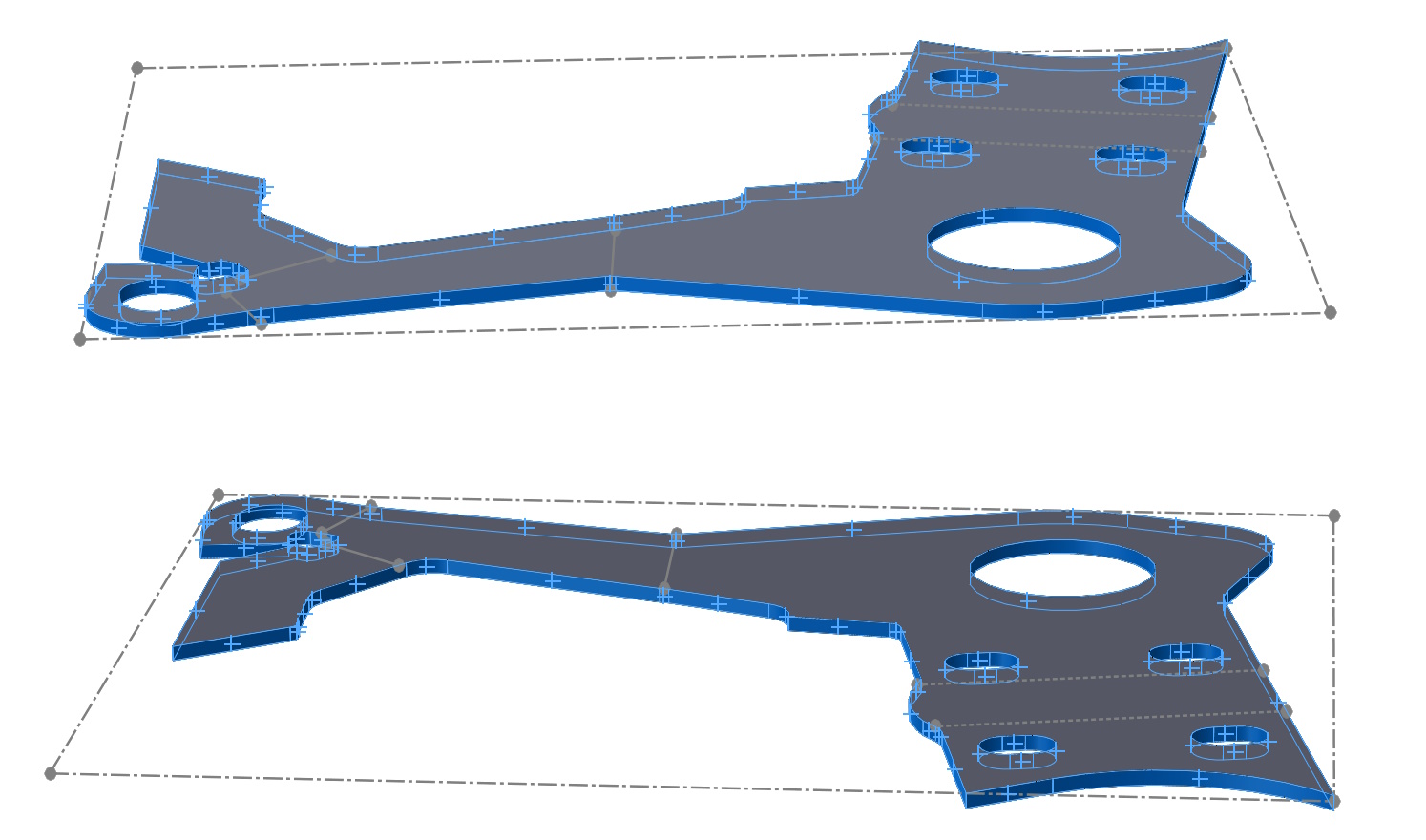

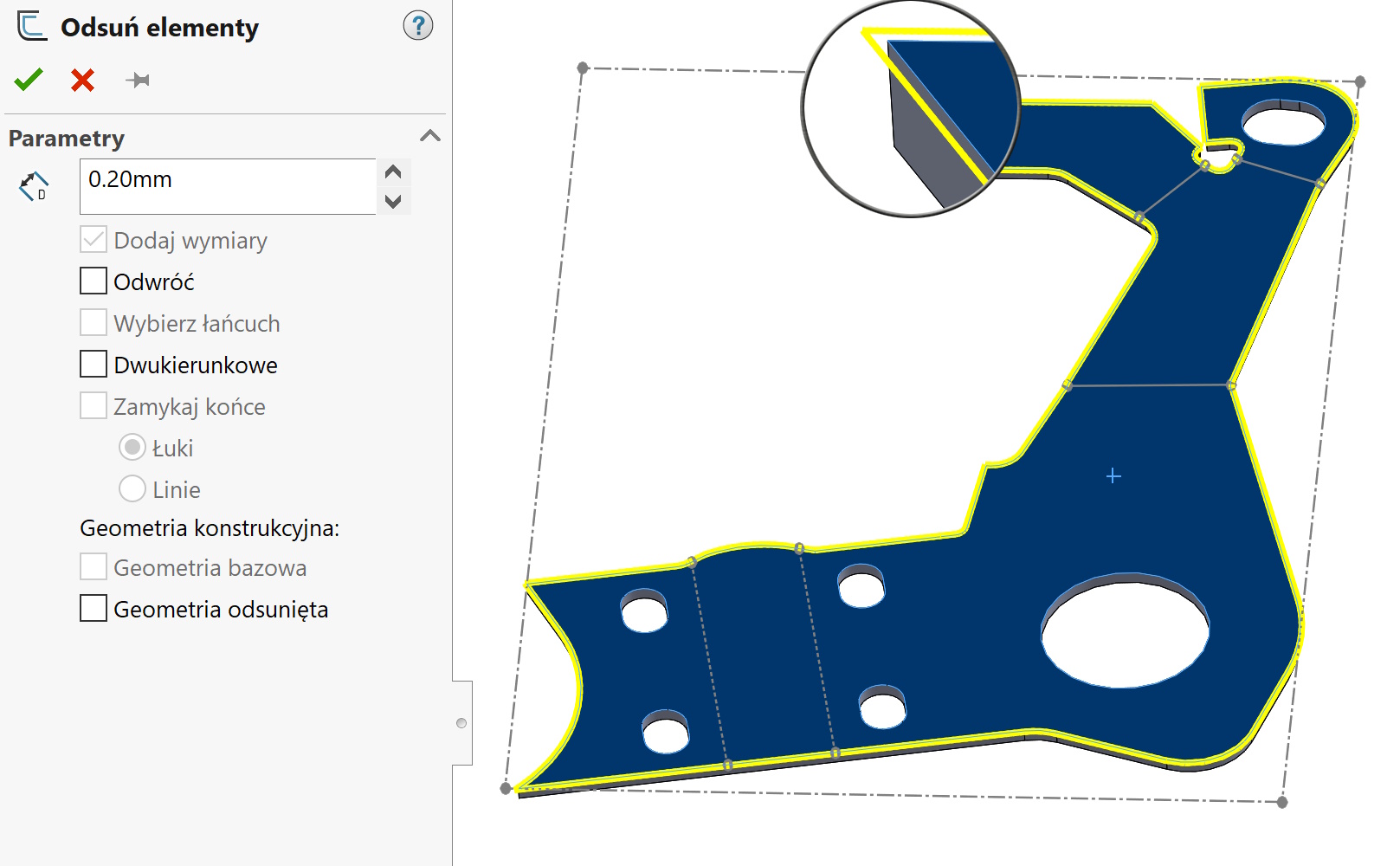

Method 2. Sketch offset.

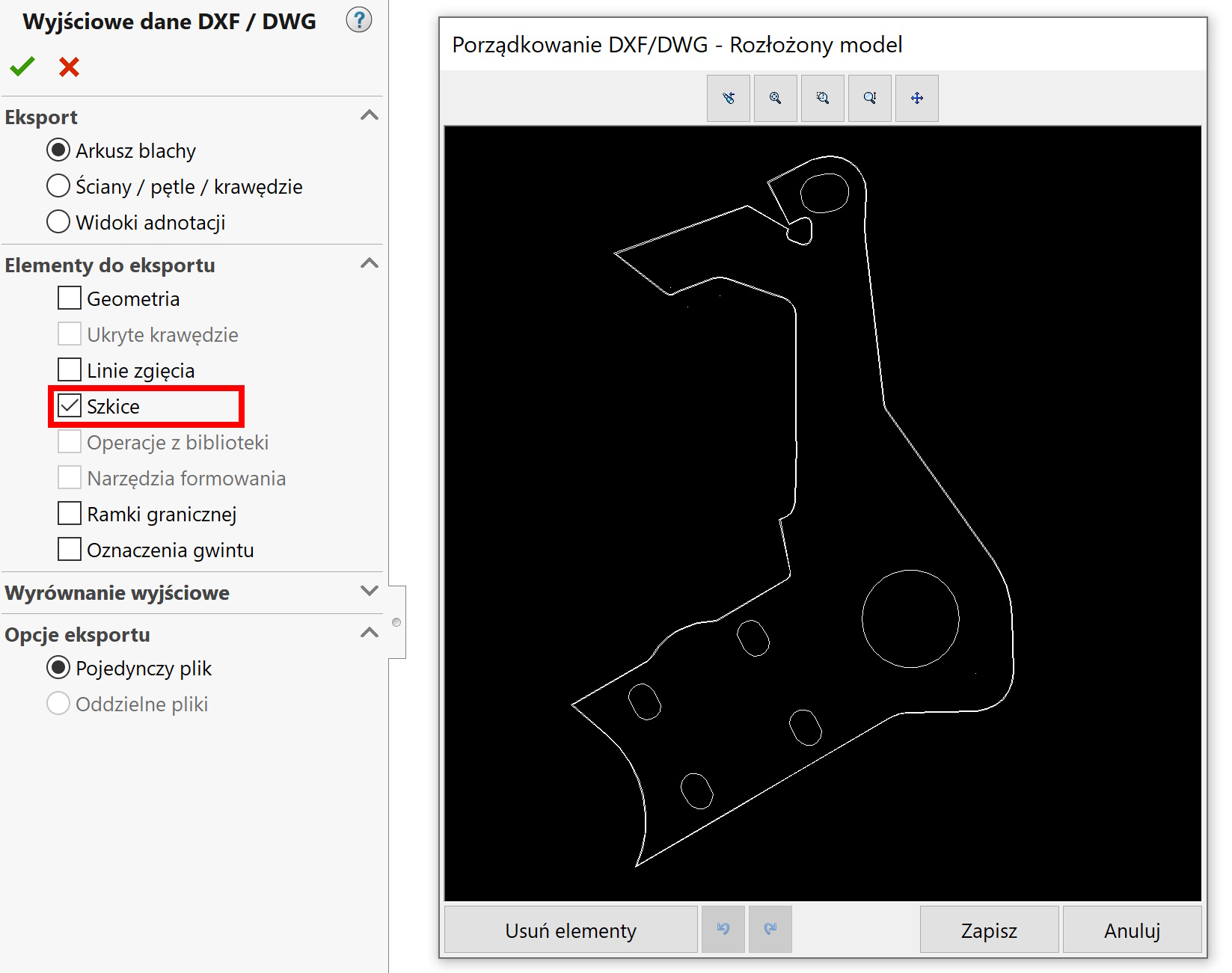

At the time, when the sheet metal is unfolded, you can insert a sketch on the upper wall and move away by the set value. In this method, we do not physically modify the 3D model. Then when saving the file in DXF format you need to select sketch instead of the model geometry and you're done!

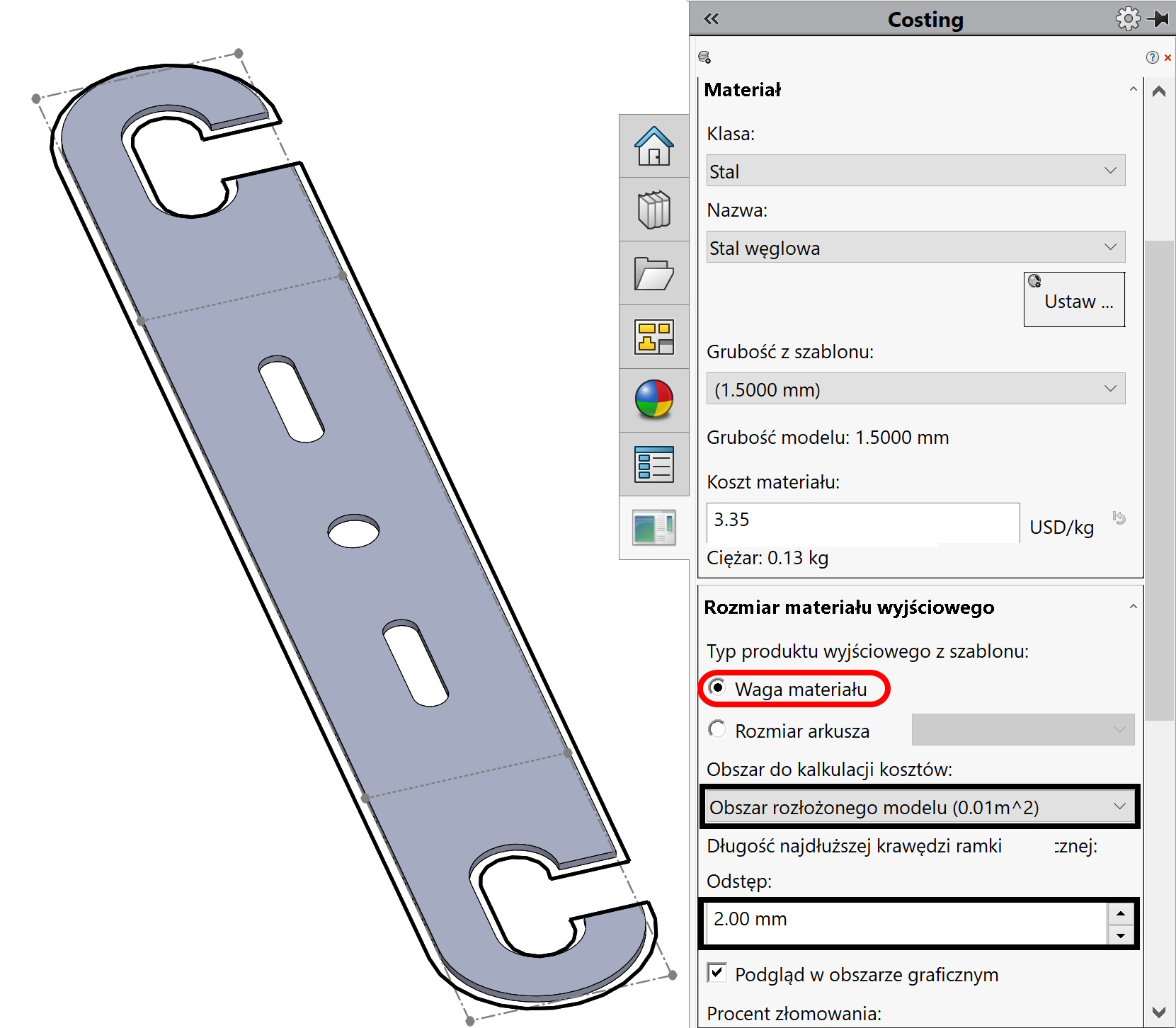

Bonus. Costing.

The Costing add-on is used to calculate production costs, among others:. sheets based on predefined costs of individual technological operations. One of the functionalities of the add-on is the ability to define an allowance for the boundary frame or the sheet metal itself. Unfortunately, such a black outline cannot be saved, but the resulting allowance can be used to calculate the costs of producing or processing sheet metal.