Do you know, that… ?

on the Review you will find a tool called Thickness analysis.

This operation is used to detect in models places with a thickness different than the assumed one.

Below are two practical examples, in which it is worth using this tool.

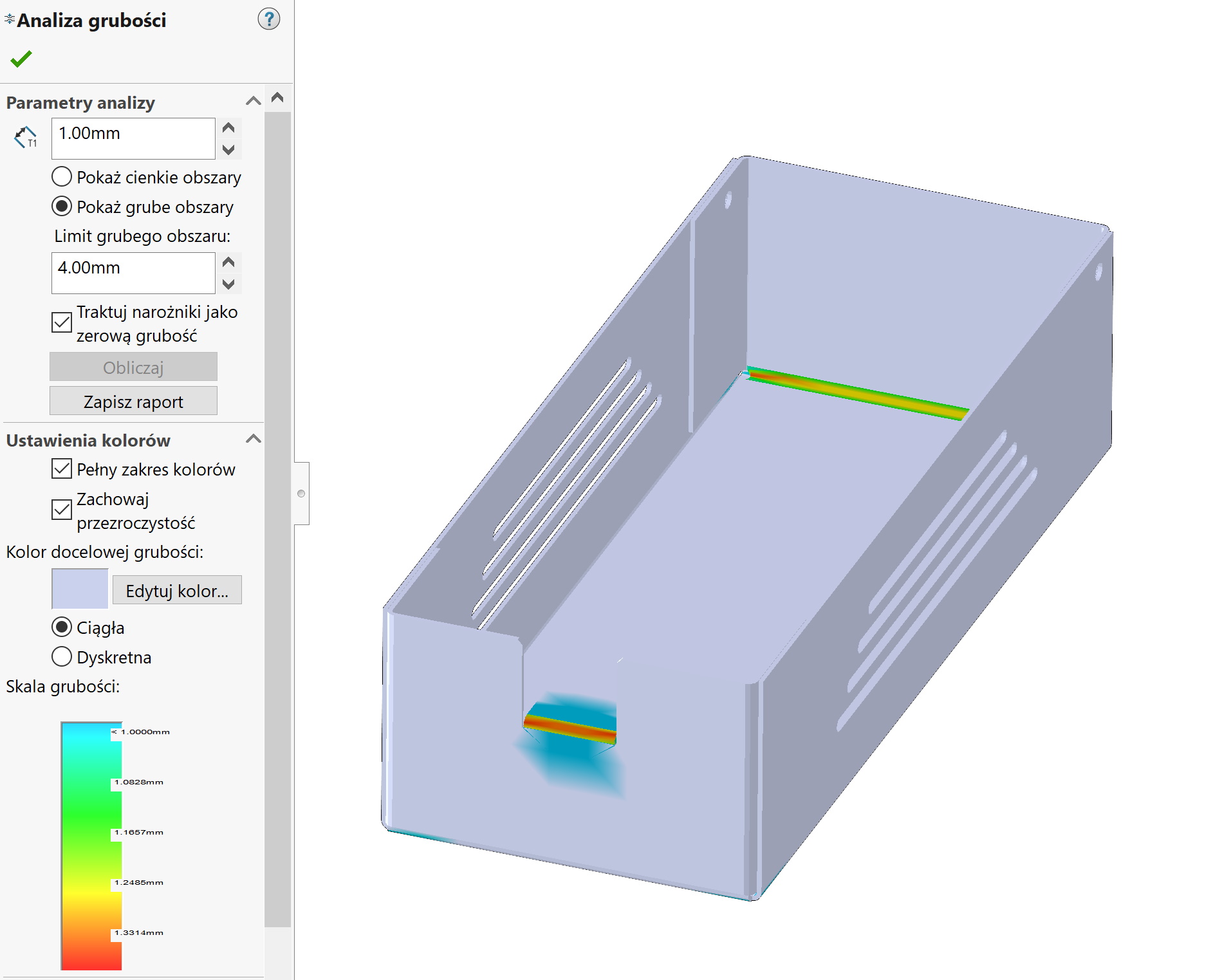

- sheet imported, e.g. provided by the customer. In the SOLIDWORKS environment, add the bend information, that is, use a function Insert bends or Convert to Sheet Metal. If the sheet thickness is not uniform – the program will not convert the model into a plate and thus it cannot be disassembled. So using this analysis you can detect and repair places with a thickness different than assumed.

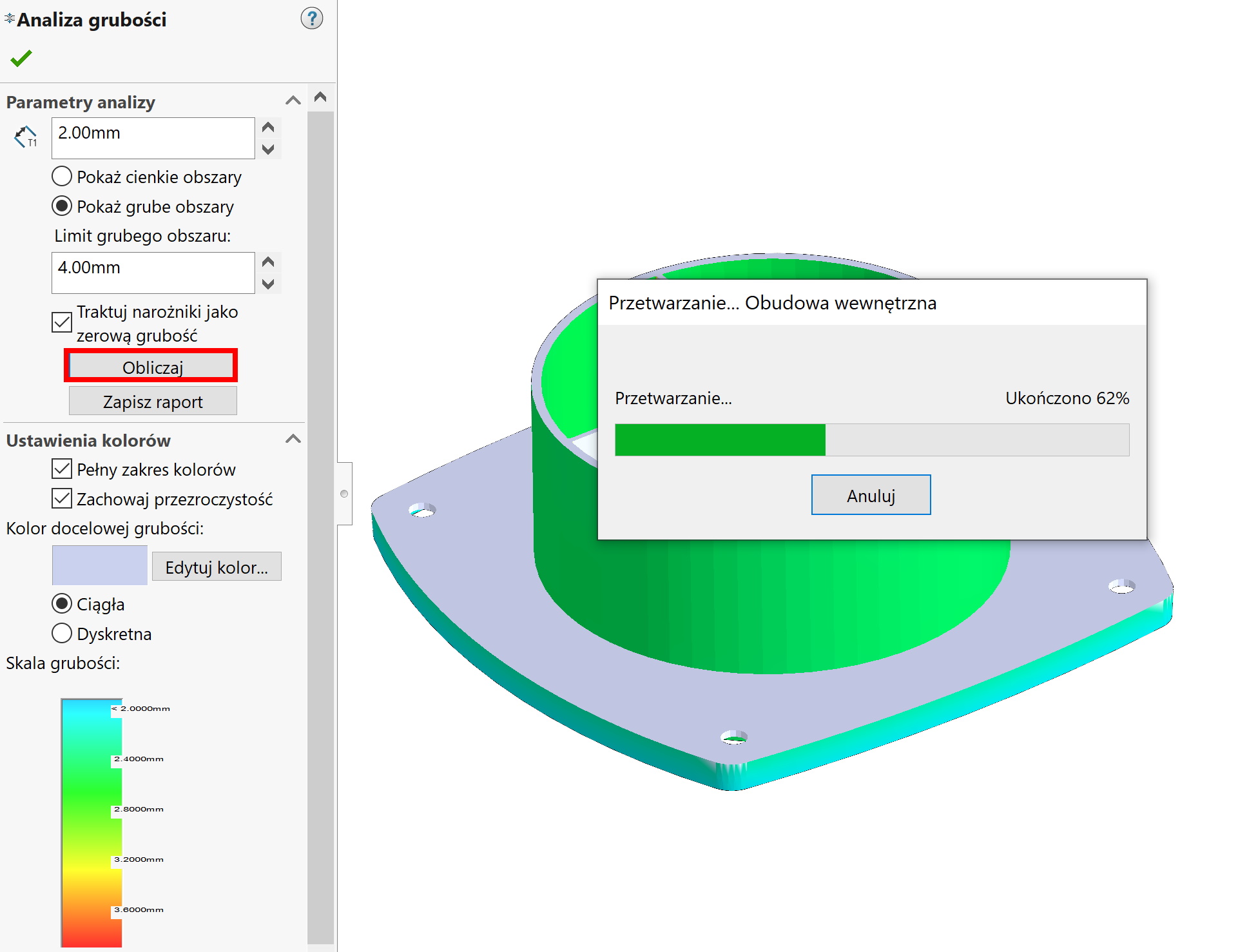

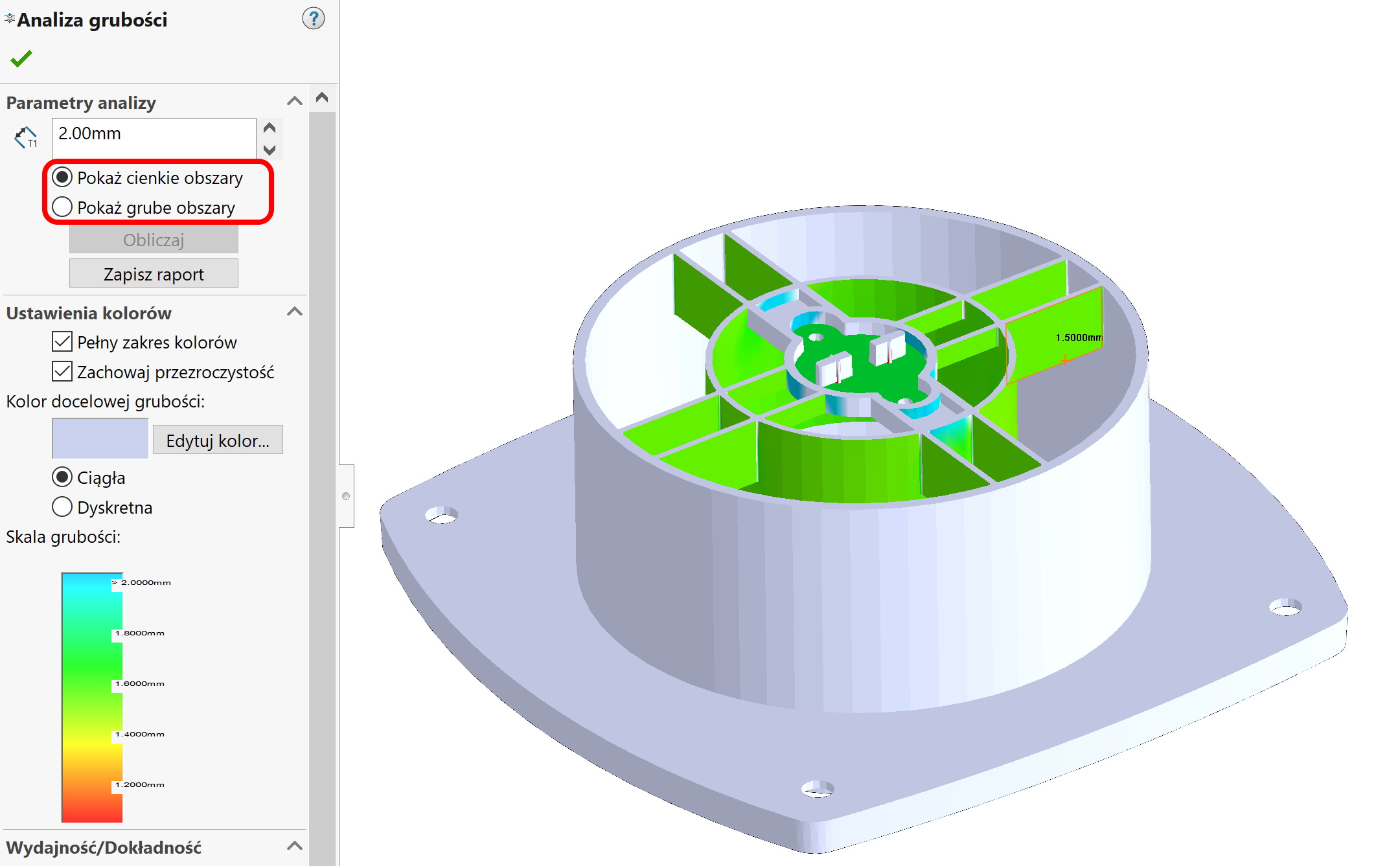

2. Plastic enclosures are the second example. Everyone, who designs the moldings knows, how important are the wall thicknesses due to the plastic injection process. Too thick places cause collapses, on the other hand, too thin may result in this, that the material will not reach all areas. As you can see, the program can detect both too thin and too thick areas.

You can also steer resolution – that is, the accuracy of division into graphic triangles. However, moving the slider to the right increases the analysis time considerably, and it will not always significantly improve the quality of the results.

Leave a Reply