As is known, the FEM finite element method in calculations, is always subject to the risk of error. It results from many factors, from the given restraint and load, ending with an inappropriate mesh or incorrect interpretation of the results.

Today I will try to compare two methods based on available SOLIDWORKS tools.

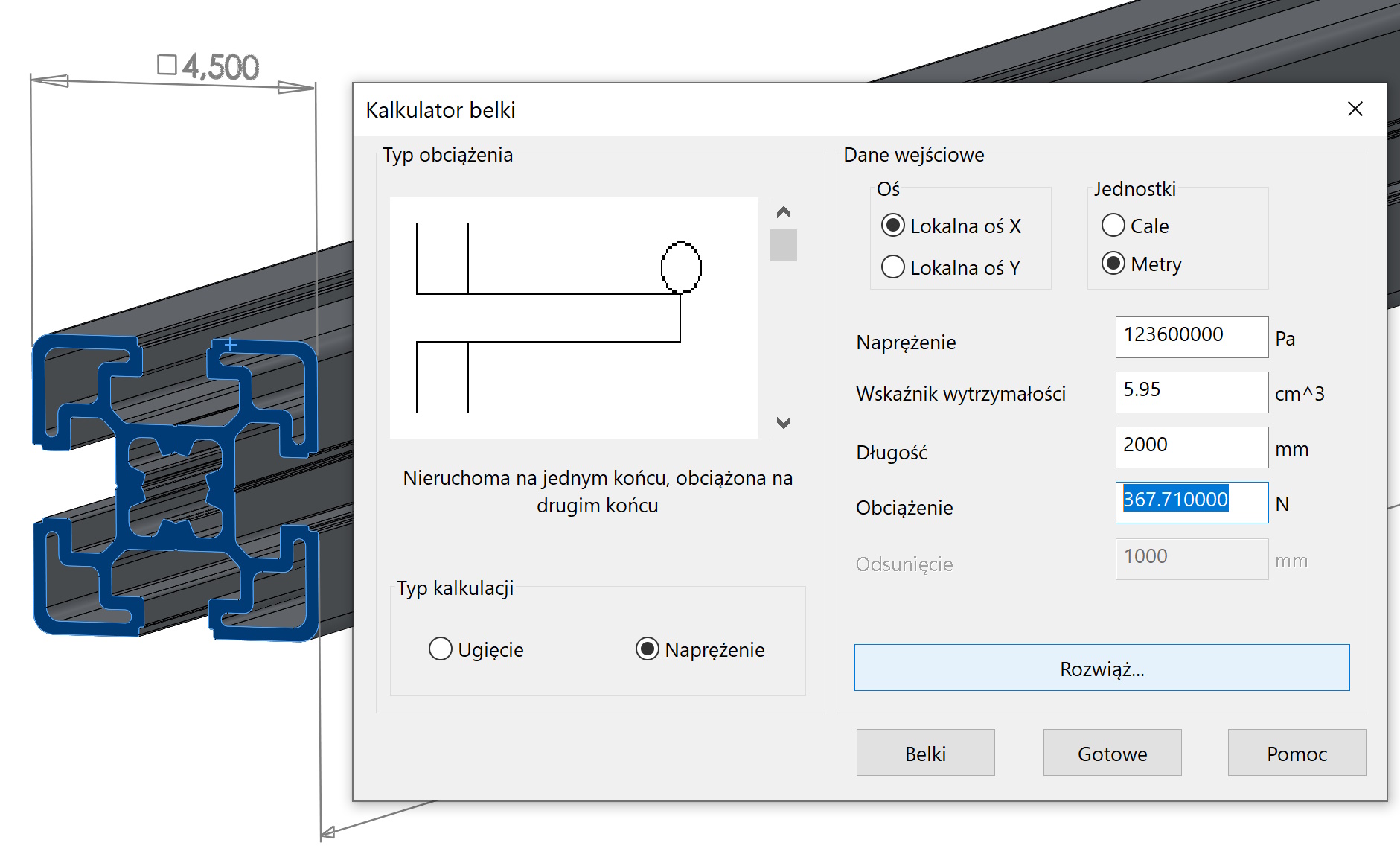

The material used for calculations is Aisi Steel 304 z Re=206 MPa. The length of the beam is 2 m.

Let's consider bending, where kg=0.6, ie. Re = 123.6 MPa.

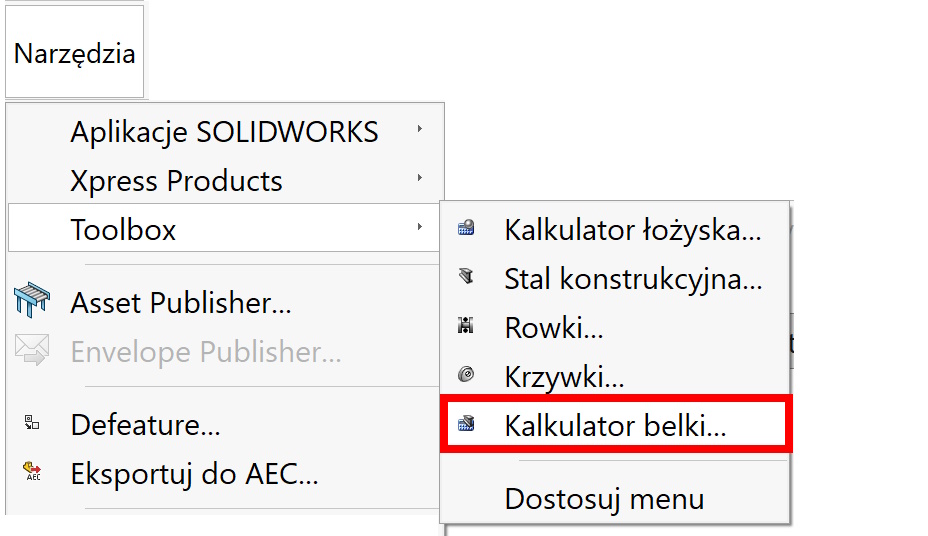

Using an add-on In machine design, users often need to make repetitive and its component Calculator maybe – I can calculate the allowable force and deflection.

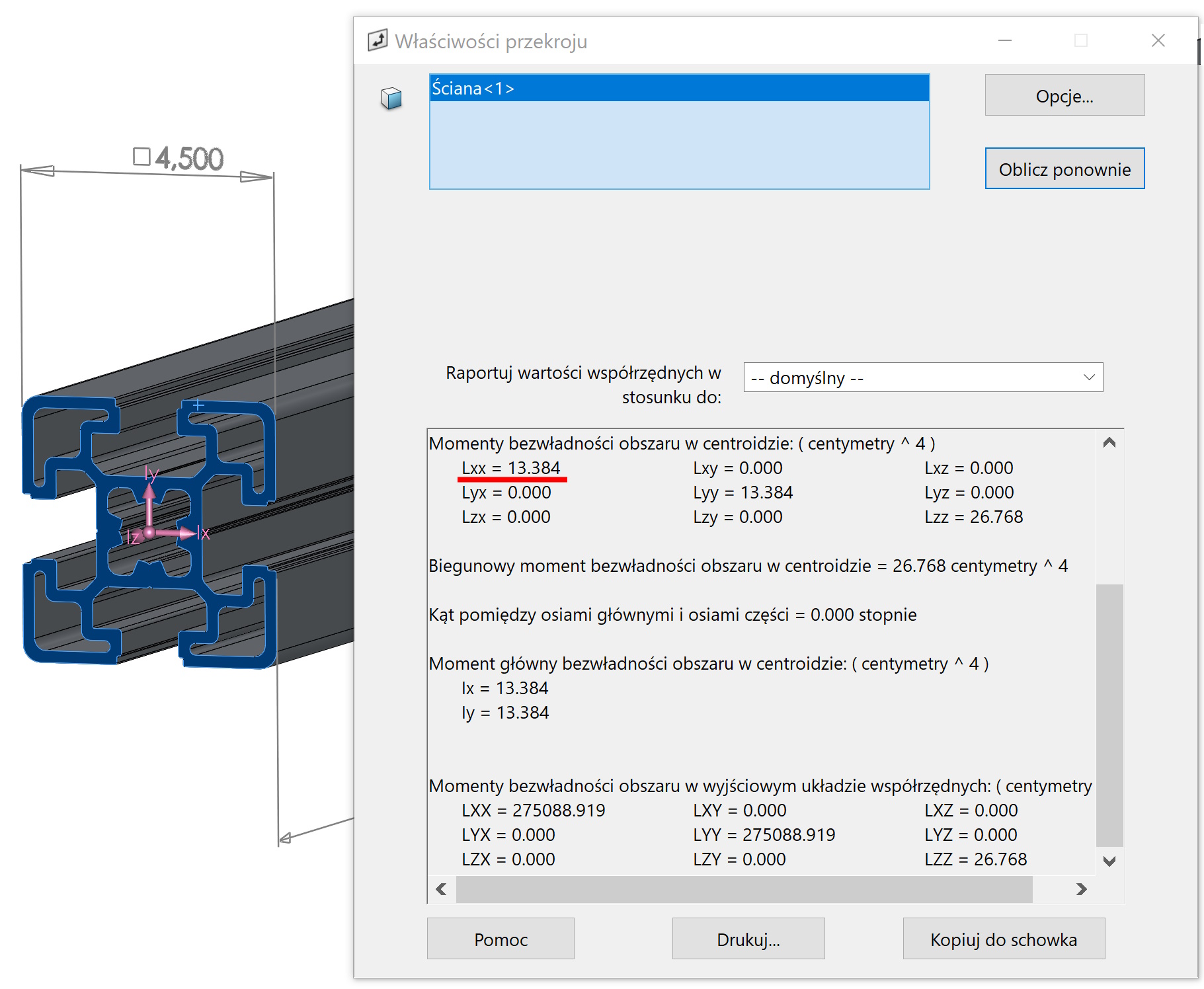

Strength index expressed in [cm] calculated from the formula:

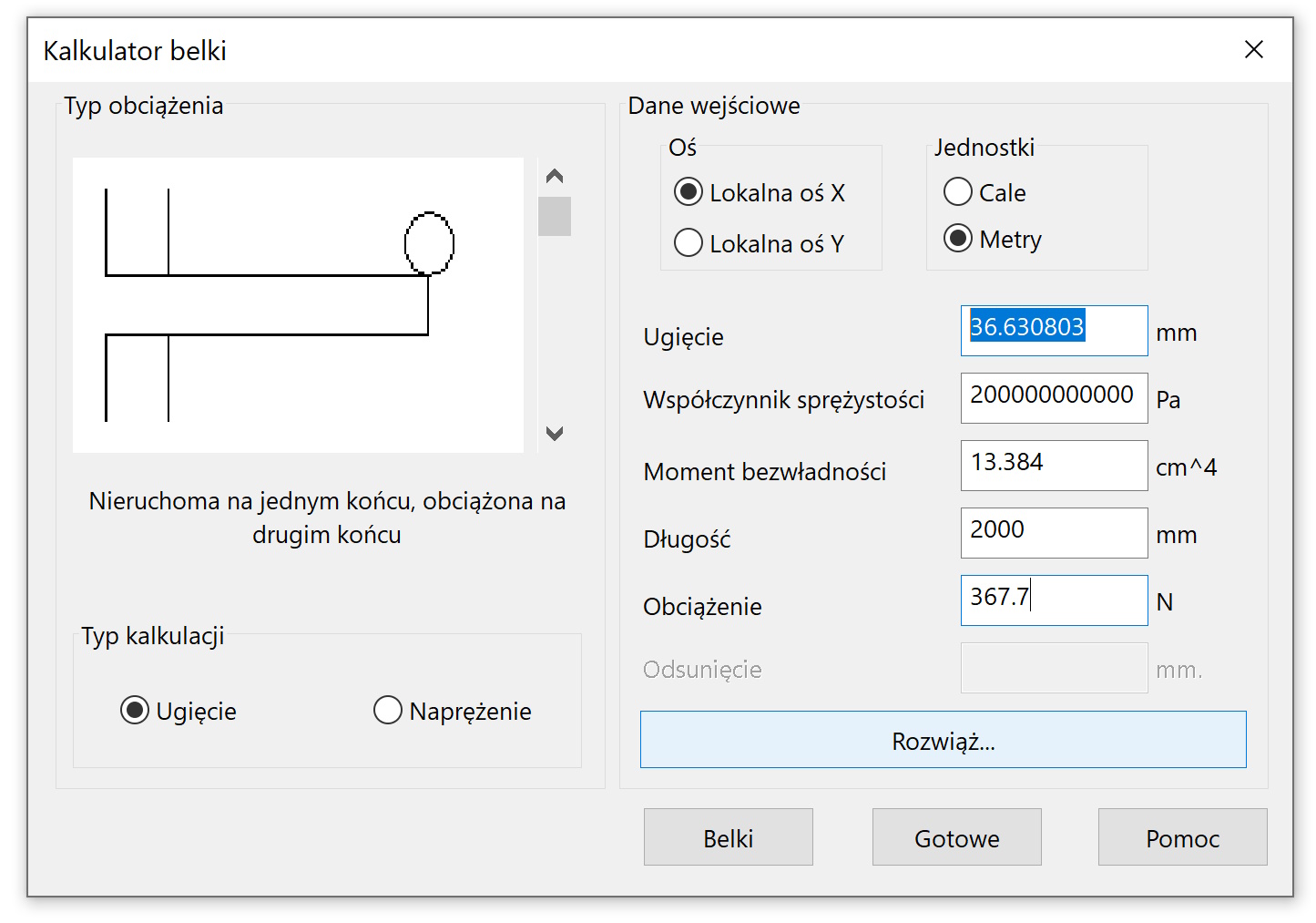

The deflection for the case in question is 36.6 mm.

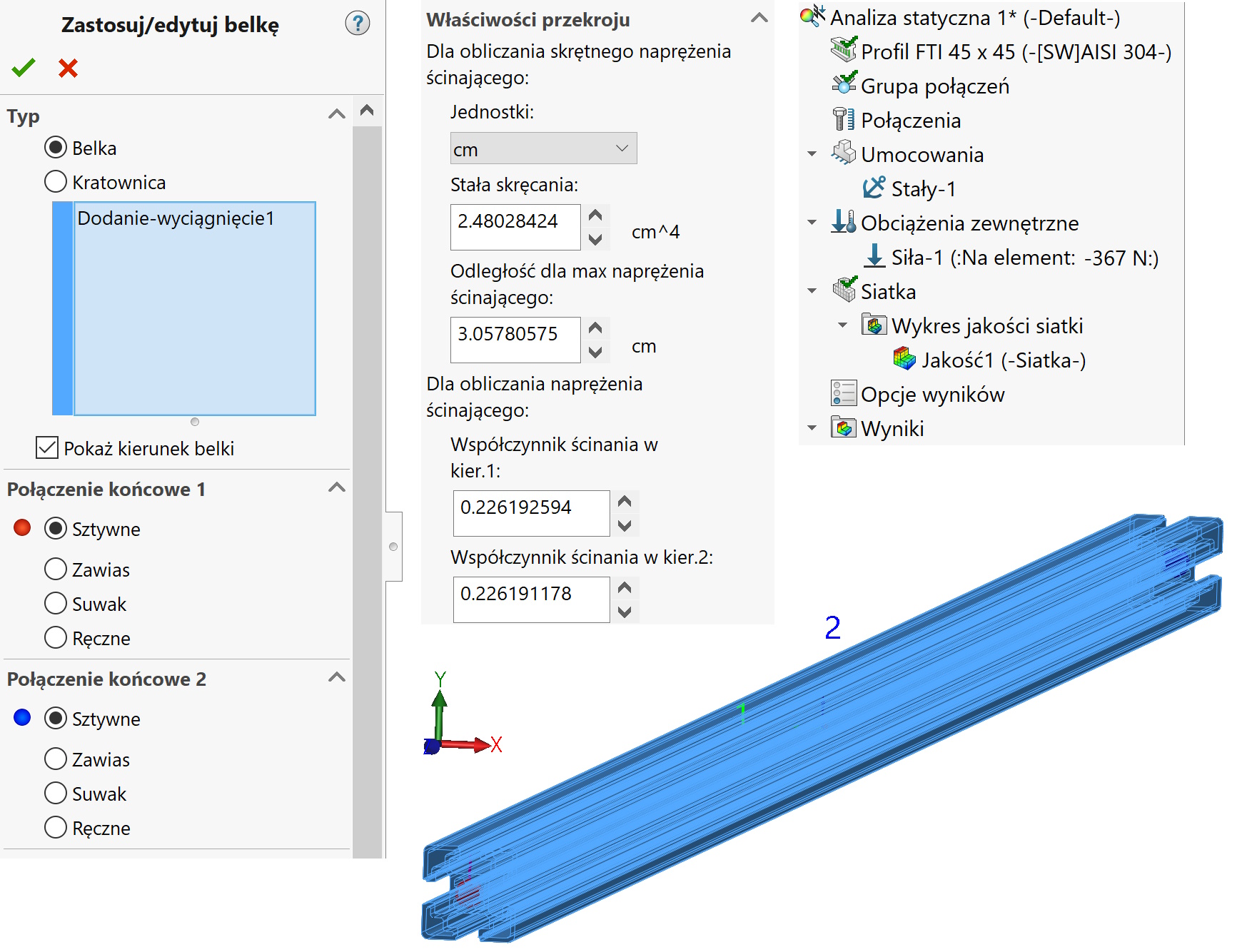

And now for comparison, the same calculation in SOLIDWORKS Simulation.

Beam type mesh, accurate. Identical support, the assumed load is 367 N.

From the calculation it follows, that the maximum deflection is 38.5mm – so it is very close to the analytical calculation.