W configuration table Tolerances can be controlled as follows:

- W parts you can control dimension tolerances in sketches and features.

- W assemblies you can control the so-called dimension tolerances. assembly operation. This includes bindings (angular or distance), assembly feature cuts and holes, and component patterns. You cannot control the dimension tolerances of a component contained in an assembly.

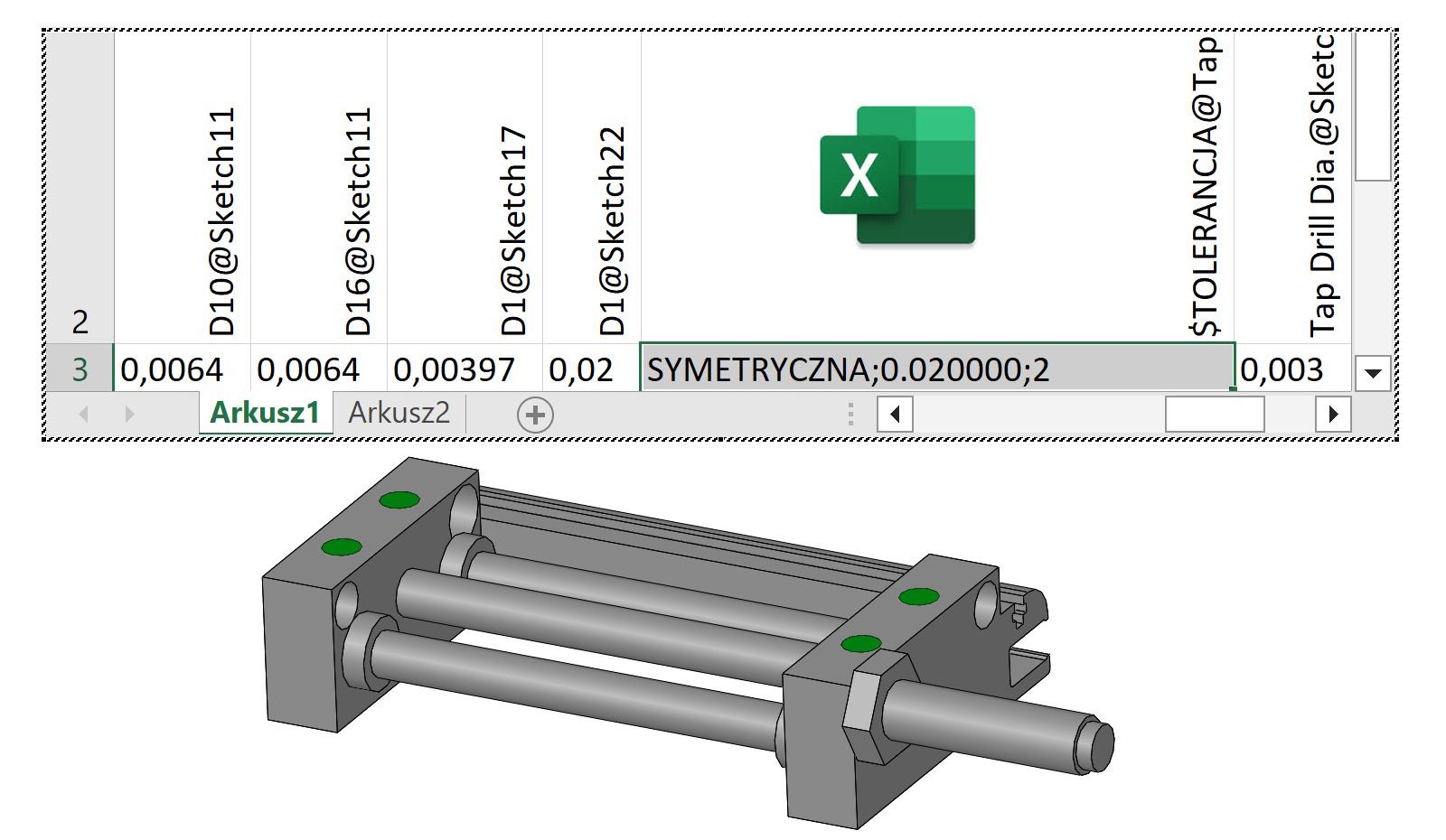

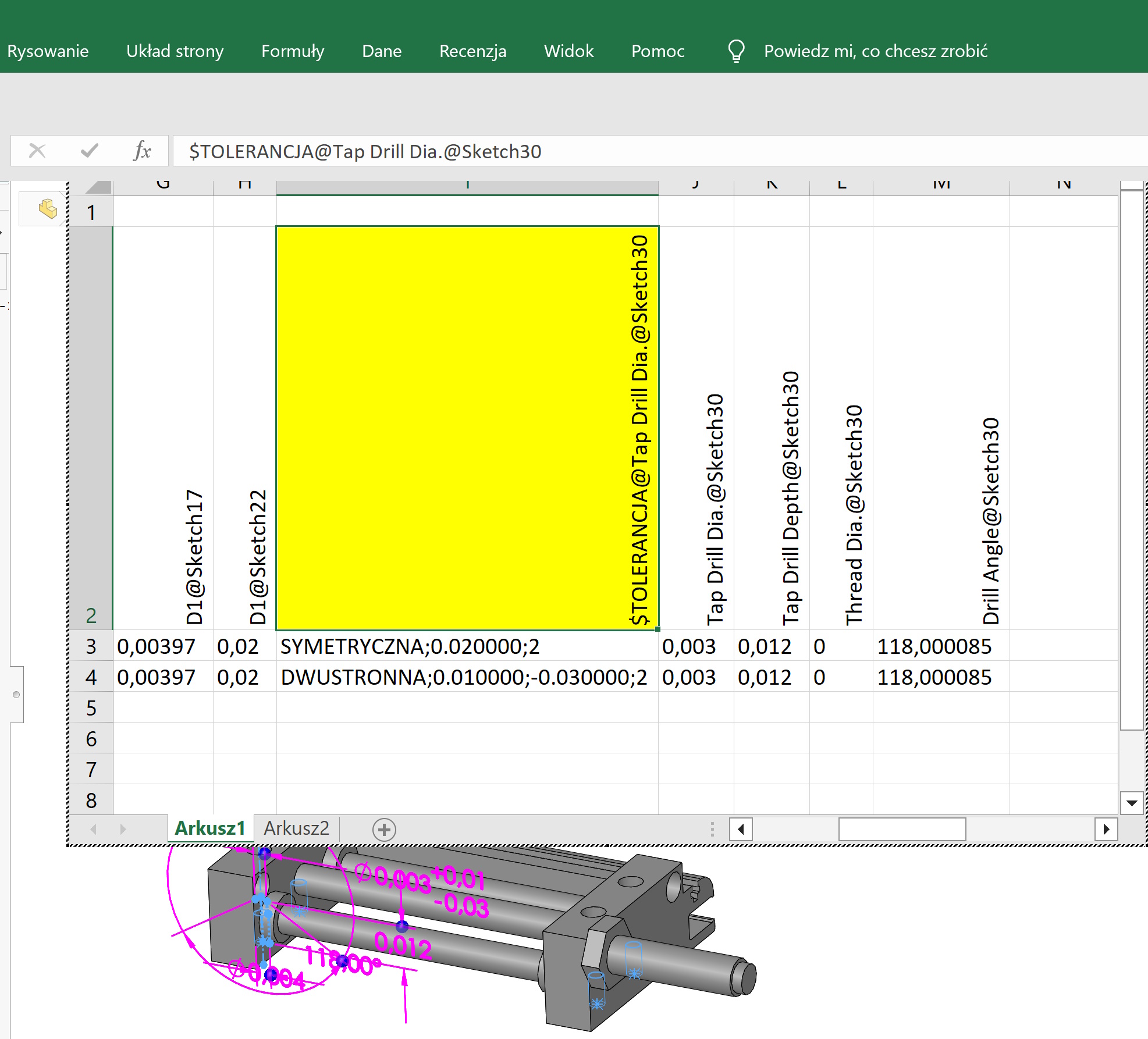

The column header in the tolerance control configuration table uses the following syntax:

$TOLERANCE@parameter name

E.g:

- the depth tolerance of the extrude feature is: $TOLERANCE@W1@Extrude1,

- distance bond tolerance is:$TOLERANCE@K1@Distance1.

When entering values for tolerances in the design table, use the following keywords and the syntax shown.

- LACK

- BASIC

- MIN.

- MAX

DOUBLE-SIDED = max_variation;min_variation

LIMIT = max_variation;min_variation

SYMMETRIC = max_variation

FIT = class;hole_match;shaft_match;match_type;max_variation;min_variation

FIT_WITH_TOLERANCE = class;hole_match;shaft_match;type;max_variation;min_variation

MATCH_TOLERANCE_ONLY = class;hole_match;shaft_match;type;max_variation;min_variation

tol_precision

where:

max_variation is positive tolerance.

min_variation is negative tolerance.

class is a general classification.

Leave a Reply