Do you know, że… ?

One of the steps in preparing the test Simulation is to create a mesh. Of course, this process should be preceded by a simplification of the geometry, but in this case I am skipping this stage.

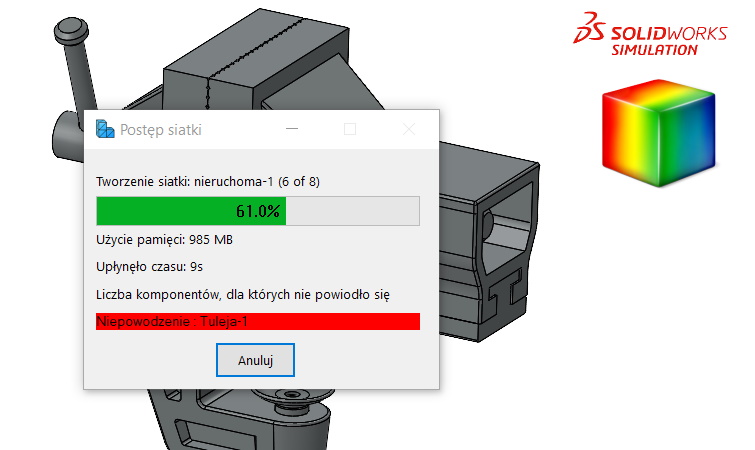

Example. An assembly consisting of several components. I create a Standard Grid with the default element size.

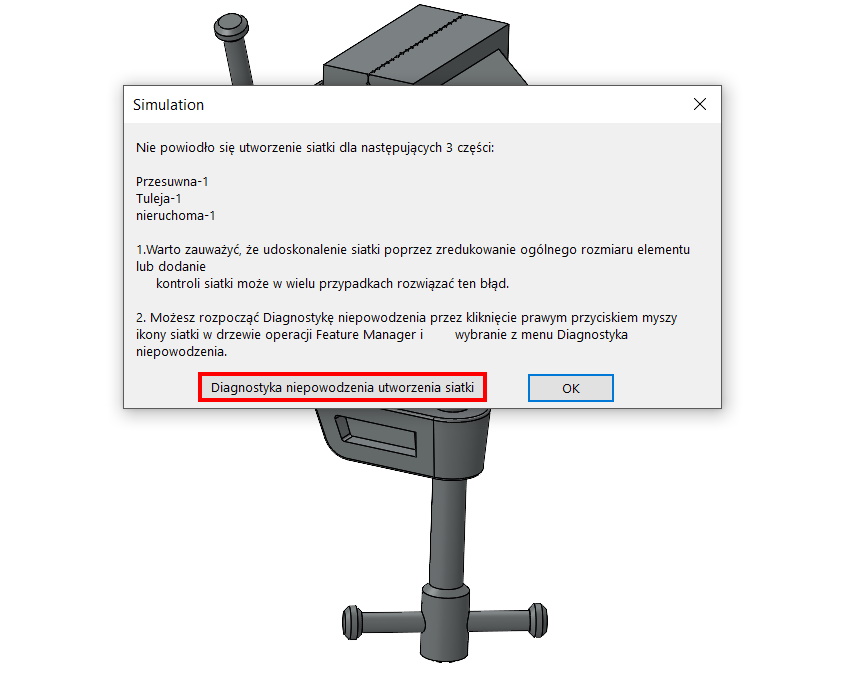

It may happen, that the mesh will not be created correctly. An error message will then be displayed, at the same time you can run Failure diagnosis.

Diagnostics shows the components, failed to mesh, and the possible causes of the problem. I close the Diagnostics window.

What can be done in this case?

I open these parts in a separate window, who have failed meshing. I create a new study and turn on the command Create a mesh. As you can see, this time the default item size is different than in the assembly. This is because, that is calculated locally, not globally for the entire assembly.

I am copying this size (CTRL + C) and go back to the assembly window.

I include in the assembly Apply mesh controls and point to the component, which a moment ago was open in a separate window. Then I paste (CTRL + V) copied size from part.

After this treatment, the mesh will be properly formed.

Of course, the procedure must be repeated for all other components, failed to mesh the first time.

attention.

The presented method works, but it is not the only possible solution to a similar problem. The meshing error can be caused by many factors and can also be resolved in many ways. Sometimes it is enough to create A curvature based mesh, and sometimes you have to turn on Incompatible mesh.