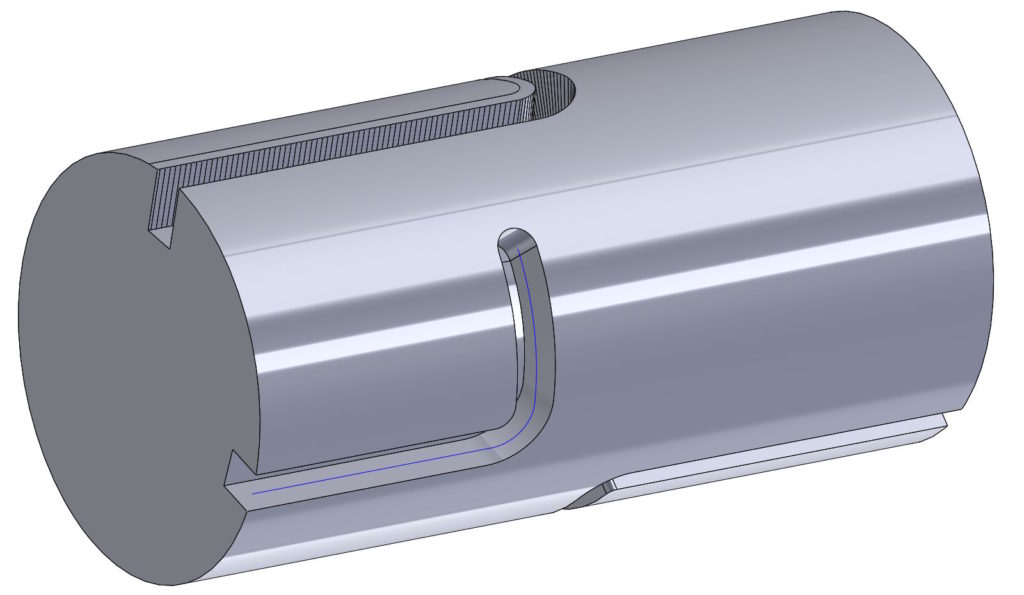

Częste pytanie na forum i nie tylko – jak poprawnie wyciąć cylindryczny rowek na walcu?

Learn three solutions.

1.Extrude the cut + Cut out by rotation + rounding.

The easiest to implement, but at the same time the least universal solution.

It consists.

Finally, add rounding.

2. Cutting on the path with a block.

This is the most obvious solution, because the requirement in this operation is to use rotary lump. This block is the equivalent of a milling machine, which collects material during processing.

The most important difference compared to the cutting on the path a sketch it is, that the material is removed anywhere in the 3D object, and not only on the cross -section.

Unfortunately, this operation does not always work, An additional difficulty may be to create the right path wrapped in a roller.

According to some people, the resulting groove differs from the actual cutting method.

3. The style of the object and the deducting of the material.

Long ago, kiedy nie było “lepszych” operacji, This type of groove could be made by the submission method. Of course, this way will work today.

Polega na stworzeniu krzywej – ścieżki na walcu oraz obiektu obrotowego. The beginning is identical to the second method.

Odnośnie ścieżki – można ją wykonać jako rzut krzywej, spline on the surface, cut, Wrap or throw the curve. However, keep in mind, iż niektóre operacje wymagają zamkniętego konturu – wówczas wykorzystujemy wyłącznie niektóre segmenty krawędzi.

Then we do chic on the curve of the object with alignment to the wall cylinder. Performance is a limitation, because it would be best to enter as many repetitions as possible (at my place 105) corresponding to the location of the cutting tool.

In the next step We subtract the created objects from the waltz (operation connect). You can connect them earlier, and then subtract, But this is not necessary.

The method quite faithfully reproduces the groove, but it is ankle, not liquids. But maybe this can be optimized directly in the CAM program when defining the processing path.