There are several important options in the weldment settings.

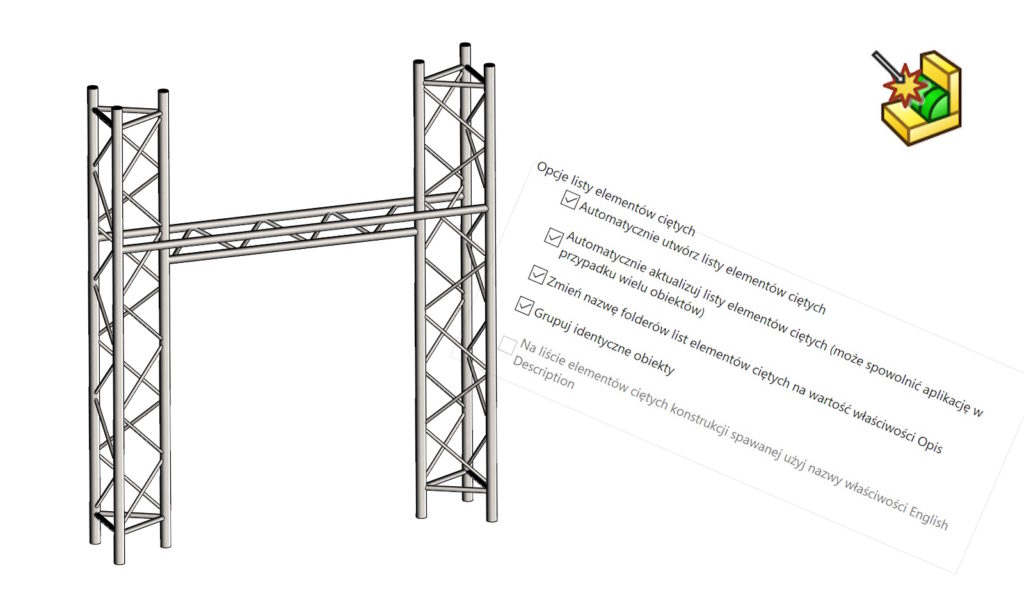

results in loading the equation or global variable into the design table Cut list options (1):

- Automatycznie utwórz listy elementów ciętych – powinna być włączona. He is responsible for it, that the cut-list is inserted automatically, a nie ręcznie – jak to miało miejsce w starszych wersjach programu.

- Automatycznie aktualizuj listy elementów ciętych – również powinno być włączone. Once, when this option was not available, many people forgot to update after making changes and the drawing was out of date.

- Rename folders (…) na Opis – zdecydowanie należy włączyć. In this case, you can immediately see the name of the pipe type in the tree, angle bar etc. instead of Cut list item.

- Group identical objects is responsible for this, that if two identical solids are created by different operations, the program will put them into one folder.

Weldment options (2) they are responsible for creating additional derived configuration <welded>. Creating such a configuration is checked by default, but is it needed? You should answer yourself, are you using this configuration. unless, you can safely uncheck this option. Just remember one fact, that is the default configuration <welded> is downloaded to the drawing to create a bill of materials. But if it's not in the template, the program will use <machined>.

Also read:

Then on the card weldments is Description of sheet metal bodies. It is puzzling, why plate options are on the weldments tab, skoro we właściwościach jest oddzielna kategoria Arkusze blachy… to było pytanie retoryczne. Definitely an option to move elsewhere.

The last settable element of this card (3) is Generate ID of cut list. You can specify here, what properties are glued together into one string creating the structure identifier, plates or simple multibody parts. This option is not selected by default. If such an identifier would be useful for something, you can configure and enable it.